APM WINMACHINE FEATURES

APM WinMachine - CAD / CAE computer-aided calculation and design of mechanical equipment and structures in the field of engineering, developed with the latest advances in computational mathematics, the field of numerical methods and programming, as well as theoretical and experimental engineering solutions. This system fully takes into account the requirements of state standards and regulations relating to both the design of the design documentation, as well as to the calculation algorithms.

APMWinMachine

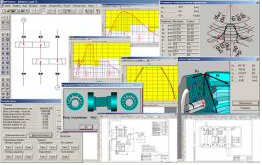

APM Structure 3D - APM Graph - APM Studio - APM Bear - APM Cam - APM Drive - APM Joint

APM Plain - APM Screw - APM Shaft - APM Spring - APM Trans - APM Base - APM Dynamics

APM WinMachine has broad functionality for creating models of structures, perform the necessary calculations and visualization of the results. Using these features will reduce design time and reduce material structures, as well as reduce the cost of design work and production as a whole.

Design tools and machine parts - Strength analysis of components and structures - Design of joints - Recommendation - Certification

Available in the system APM WinMachine settlement and graphics tools let you tackle abroad range of applications :

Calculate themechanical equipment and its components using engineering techniques

Analyze thestress-strain state (using the finite element method) of three-dimensionalobjects of any complexity for arbitrary binding, static or dynamic loading. Create designdocumentation in accordance with ESKD

Use when designing a database supplied standard products and materials, as well as create theirown database for specific activities of the company. Advantage of integration with third-party graphics packages to work with pre-existing spatial models and drawings

System APMWinMachine x64 :

SEC releases APMAPM WinMacine system in two configurations: one for 32-bit and 64-bitsystems. WinMachine x64 APM includes a full functional 32-bitversion. Using the 64-bitversion allows you to:

speed up the calculation procedure to several thousand times depending on the specific problem solve problems without formal restrictions dimension. Actual dimension of the limited amount of RAM.

greatly acceleratethe procedures for working with a group of geometric objects to create models

System APMWinMachine includes :

drawings and asingle graphical environment - database and its control system - basic computational kernel - module of finite element (strength) analysis

APMStructure3D modulus of thekinematic and dynamic analysis of linkages APM Dynamics

calculation module bolted, welded, riveted joints and connections of parts such as bodies ofrevolution APM Joint

engineering analysis tools machinery parts with the possibility of automatic generation of drawing documentation tools automatically generate finite element meshes with fixed and variable steps,with the ability to interactively change the parameters of the partition meansimport geometry models designs from third-party graphical editors using formats STEP, SAT and DXF

In the composition of drawings and graphic environment includes:

flat parametricdrawing and editing editor for creating spatial structures

pre-processor training models for finite element analysis (with support for importing filesSTEP, SAT and DXF)

DBMS and thedatabase -Design tools and machine parts

module forcreating and editing databases

database of standard elements for design engineering drawings

information database for the design process library of standard metal sections database parameters of materials database parameter sections

With the help of APM WinMachine can:

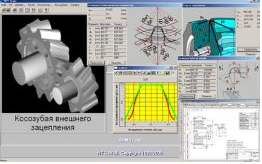

Engineering to perform calculations and checking mechanical gear rotation to give the full geometry, the definition of control parameters and tolerances, as well as automatic generation of detailed drawings

conduct checking calculation of shafts and axles (static and fatigue calculation and calculation of dynamic characteristics of the shaft), followed by visualizing the results in graphs and tables as well as automatic generation of drawing designed shaft solve design problems rolling bearing assemblies and sliding with key operating parameters

automate the design of the drive rotary motion of any structure with the generation ofdrawings of individual parts and assembly drawing creation

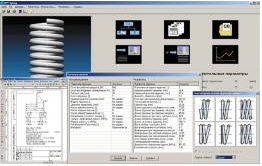

expect elastic elements machines , performing Engineering & checking calculations and calculations of standard springs selection followed by automatic generation of detailed drawings make test calculations Transmission translational motion design cam mechanisms with progressive rocker pushers or when entering an arbitrary function of the mechanism to give the cam profile and animation work, as well as automatic generation of drawings conduct kinematic and dynamic analysis of linkages to obtain graphs of trajectories, velocity, acceleration,force factors, as well as the animation of the mechanism

Design of joints Design tools connections APM WinMachine system designed to design and analysis of cluster screw and rivets, welds, connections parts of bodies ofrevolution

of designing and checking calculations under constant and variable loading conditions in accordance with EU standards and SNIP

determine the optimum geometrical parameters of compounds

issuance text report with color cards results in user-friendly form

Certification

Estimated system kernel APM WinMachine - module APMStructure3D - has a certificate of conformity № ROSS RU.SP 15.N00327 (GOST Rcertification system Russian State Standard) requirements of the following regulations:

SNIP 2.01.07-85 * ("Loads and effects")

SNIP II-7-81 ("Construction in seismicregions")

SNIP II-23-81 ("Steel Construction")

SNIP II-22-81 ("Stone and reinforced masonrystructures")

SP 52-101-2003 ("Concrete and reinforcedconcrete structures without prestressing reinforcement")

SP 50-101-2004 ("design and layout of the foundations of buildings and structures")

SP 50-102-2003 ("design and layout of pile foundations")

STO 36554501-002-2006 ("Wooden laminated andsolid wood construction. Methods for design and analysis")

GOST R ISO 9127-94 ("User Documentation and Information on the packaging of consumer software packages")

ISO / IEC 12119-2000 ("Information Technology.Software packages. Quality requirements and testing")

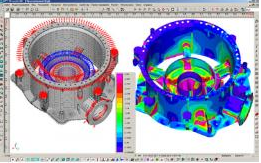

Strength analysisof components and structures Tools finite element analysis of parts and designsavailable in the APM WinMachine, you can:

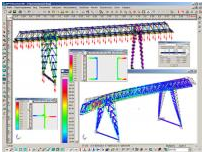

prepare for the calculation model structure using rod (bar, farm, rope), plate (triangular, rectangular), solid (4, 6, 8-nodal)finite element

indicate the locations of consolidation and makethe necessary permanent or time-varying load

conduct a wide range of different types ofcalculations to determine the distribution of stresses and their components,linear, angular displacements, strains, internal forces of natural frequencies and their own forms of safety factors for strength or durability of the material

determine the factors of safety and buckling ofstructures

carry out the calculation of forced vibrations on schedule changes forcing efforts animation oscillatory process

receive safety factors and the number of cycles by the fatigue strength

a calculation of temperature fields and thermal stresses in structural elements

partially or fully prepare metal geometric model,using the library the most common types of schemes

validate bearing capacity and automatically select the optimal cross-section of the rod member (criteria of strength andstability, as well as in accordance with the requirements of SNIP II-23-81)from a library of standard sections or from a library prepared by the user

automatically get drawings standard units of metal compounds

prepare drawings projection model construction as a whole and its individual parts get a table consumption (materials and profiles) onthe rod members calculate the estimated combinations (DSCs)

calculate the contact interaction