Strength calculation of the locomotive. ZAO UK "Bryansk Engineering Plant"

"ZAO UK" Bryansk Engineering Plant "(BMZ), one of the largest factories of transport engineering, is one of the oldest enterprises of machine-building industry of Bryansk. The company was founded in 1873 as a metallurgical plant for the production of rails and fastenings. Currently, BMZ specializes in the production of locomotives, rail cars, diesel engines for locomotives and ships, as well as welding equipment, equipment for oil and gas pipelines, etc. In addition, the company also represented metallurgical direction, allowing to make steel and nonferrous castings, finely rolled, hardware, etc.

Software Product Research and Development Center APM (Korolev), computer-aided design system WinMachine Bryansk Engineering Plant used in the project of creation of modern locomotives, since 2001.

Reasons for settlement and design office stopped to use the name of this software - it is, above all, a Russian interface modules System APM WinMachine, building it on the basis of national standards, regulations and design principles that allow easy development experts Systems and its rapid implementation into production. Not the least role in the selection of software and played its price, which is several times lower than similar imported software.

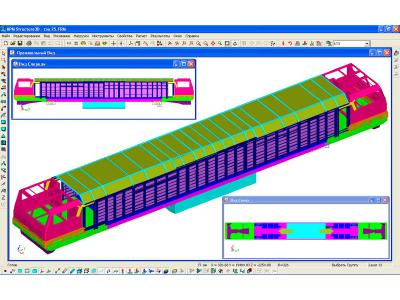

We used the system modules APM WinMachine at all stages of the design of modern locomotives, from conceptual design to the creation of technical documentation and its implementation in production. Calculation and design work is carried out on the basis of the design of individual components of the locomotive, and all of the locomotive as a whole. In carrying out the settlement and design work and promotion stages of design all the models are complicated and improved and modernized.

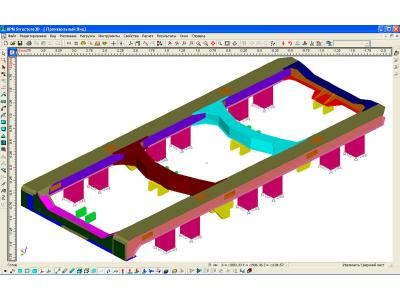

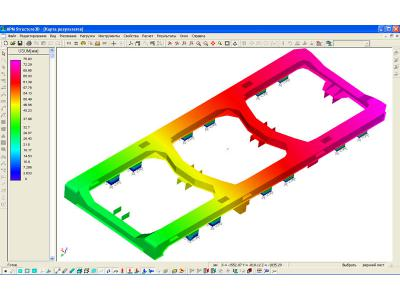

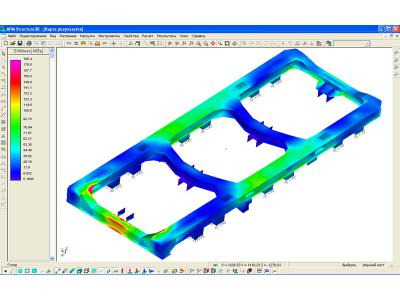

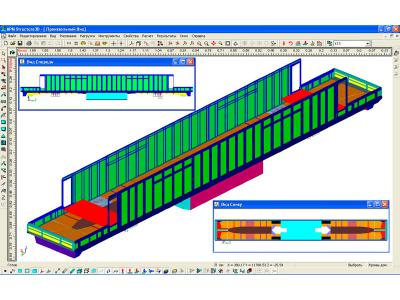

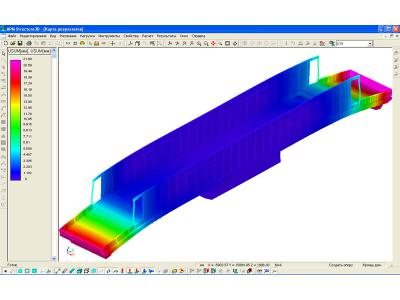

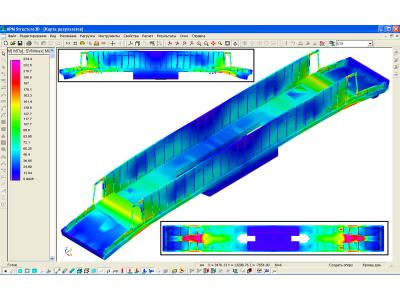

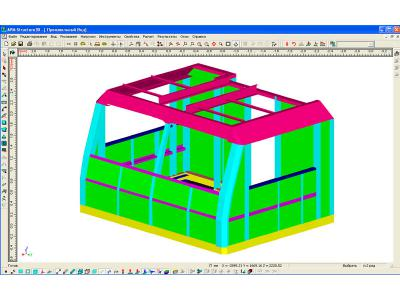

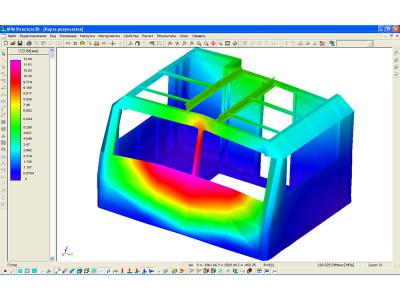

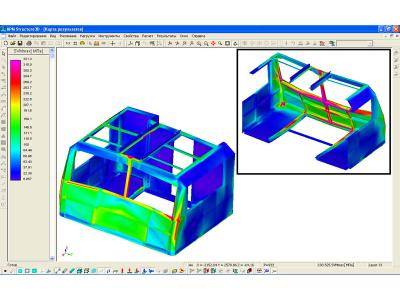

Strength calculation and individual components and the entire design of the locomotive was carried out using the finite element method. For this purpose the module strength calculation of the APM Structure3D , the editor of which were created computational models. Finite element models bogies frames, main frames, cabs and bodies allow locomotives to perform not only Strength static calculation specific design options, but also to carry out research and offer the modernization of these structures. The purpose of modernization - the optimization of the parameters of the upgraded nodes, while maintaining their overall performance.

In addition to conducting the static structure analysis to determine its stress-strain state, the module APM Structure3D allows settle on their own (resonance) frequency and receive their own forms structural oscillations at these frequencies, and forced vibrations to determine the behavior of the structure at the known dependence of forcing vibrations from time.

These models have allowed the locomotive to conduct research, static traction qualities of diesel locomotive. The result of these studies was to determine the traction force of the locomotive traction on the rails. We investigated the effectiveness of various thrust transmitting device with trolleys on the body of the locomotive and various mechanisms radial installation wheelset axles.

Besides the above problems by diesel model and its individual components allow a study on the stability of both individual elements and the structure as a whole, with its subsequent working off that also is important to ensure operability and safety produced locomotives.

Based on the results of the calculations and research Bryansk Engineering Plant built the first prototype of the modern locomotive TEM21, which passed trial operation and is currently on trial. And just at the stage of implementation of the project is a new locomotive TEA - 25. "

NI Nikiforov, head of the settlement and the design bureau

Manahova LP, a design engineer first category

CJSC "Managing company BMZ"

241015, Russia, Bryansk, ul. Ulyanov, 26

Phone: (4832) 51-40-30, 54-82-20

Fax: (4832) 54-83-99, 73-67-02

http://www.bmz.032.ru

an e-mail: commerce online @ .bmz.032.ru