ASCON GOLFSTREAM

OVERVIEW

TECHNICAL INFORMATION

INFORMATION MATERIALS

CERTIFICATES

OVERVIEW

GOLFSTREAM - A system for automated control of discrete custom production

Portfolio Management

- Accounting for applications for the manufacture of products

- Preliminary assessment of the production load on the execution of the application

- Maintaining a portfolio of production orders in relation to contracts

- Formation and control of the main production program of the enterprise for the planning period

- Evaluation of the feasibility of a critical resources production program

- Formation of production specifications for each item of a production order

- Accounting for completed orders and shipments of products to customers

The system provides the following features of automated information support for management processes:

Resource production needs analysis

- Assessment of gross and net requirements for materials (basic, auxiliary)

- Needs assessment of technological equipment

- Needs assessment for PKI and components manufactured at the warehouse.

- Assessment of needs for production capacities and personnel

Management of procurement of materials and equipment for production

- Formation of purchase applications based on the results of needs analysis

- Formation of applications for the purchase of an item for which the insurance stock in the warehouse is normalized

- Formation of purchase orders

- Formation of nomenclature procurement plans

- Control of procurement plans and budgets for the procurement of materials and equipment for the main production

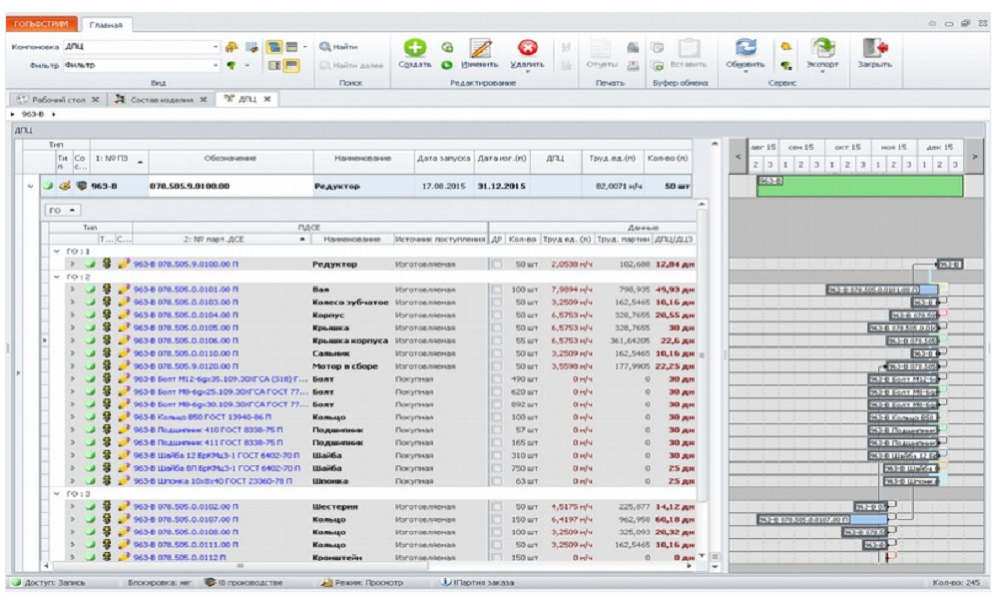

Operational scheduling of production

- Calculation of dates of launch and manufacture of DSE batches according to various algorithms, including shift plans for work taking into account the loading of work centers (equipment)

- Formation of interconnected nomenclature launch / release plans for main production units.

- Interactive analysis of the planned workload units for work centers.

- Reporting on the implementation of stock plans.

Accounting / control of work in production units

- Separation of batches of DSE in production

- Transfer of production / use of a batch of DSE from one order to another

- Operational launch of DSE batches to restore production needs due to identified inconsistencies (correctable and incorrigible)

- Accounting for the manufacture of serialized parts / assemblies and their use in serialized serialized products

- Operational control of the manufacture of DSE batches and the performance of work in any sections

- Monitoring the implementation of itemized plans of divisions and plans for the release of finished products

- Monitoring scarce (overdue) items for picking assembly units

Inventory accounting (MPZ)

- Formation of receipt and expenditure documents for each warehouse unit of the enterprise

- Accounting for the availability of items in each warehouse unit of the enterprise according to different accounting methods

- Accounting for the content of precious metals in the nomenclature of MPZ

- Address accounting of movement / storage of MPZ nomenclature in each warehouse unit

- Control of the issuance of materials and equipment for production on the basis of plant and requirements

- Accounting for finished products in storage

- Operational control of the turnover and balances of the MPZ nomenclature for each warehouse unit in various sections

Monitoring the execution of production orders

- Operational control of the readiness of production orders with any detail

- Presentation of consolidated management information on the status of orders in production in various sections

Accounting for direct costs of production

- Cost accounting for materials and purchased components

- Accounting for the costs of work performed in batches of DSE

- Cost accounting for processing services (cooperation)

- Order accounting of direct costs in accordance with Federal Law No. 275-FZ

Technical and economic analysis of production

- Formation of planned cost estimates for each order

- The formation of the actual cost estimates for the group of direct cost items to assess the average cost of the product in each completed order

- Plan-factual analysis of costing by cost item

The system implements open source business logic code. It is a platform for the development of automated production management of complex products in enterprises in accordance with their specifics

TECHNICAL INFORMATION

INFORMATION MATERIALS

CERTIFICATES