AREAS OF USE

- Engineering

- Defense Industrial Complex

DESIGN PREPARATION OF PRODUCTION

The design preparation of production at a modern enterprise is the design of products in CAD systems under the control of PDM systems. The use of a set of reliable IT tools allows us to provide quick, convenient and transparent work on the project, manage changes and organize team development.

The ASCON solution for the design preparation of production, which includes KOMPAS-3D, LOTSMAN: PLM products and NSI Reference books, closes various product development tasks.

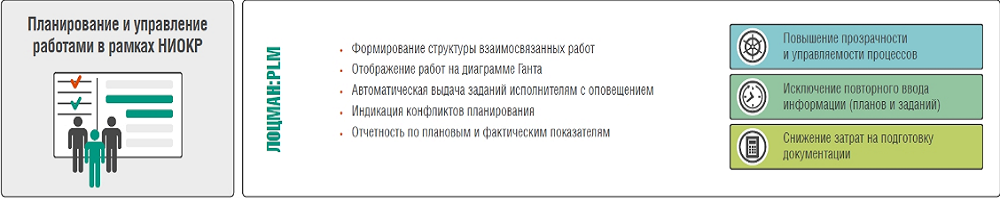

Building an effective product development process is only possible with good planning and management. For planning in the framework of R&D, ASCON offers the LOTSMAN system: PLM, which ensures collective work on projects, the formation of a structure of interrelated stages, the issuance of tasks to executors, and also allows managers to track the implementation of these tasks. The system has the ability to indicate planning conflicts, display processes in the form of Gantt charts, and create reports on planned and actual indicators.

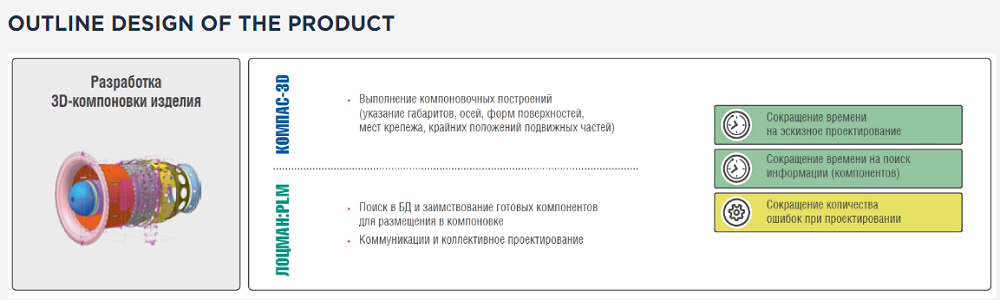

At the stage of preliminary product development in the LOTSMAN: PLM system, its structural composition is determined in the form of a list of main components. Moreover, if such nodes are already present in another project, there is a possibility of borrowing them for the current project. All information available at this stage (for example, overall dimensions, location of the main components, main axes, boundaries of movement of moving parts, etc.) is entered into the KOMPAS-3D CAD system in the form of auxiliary surfaces, curves, points, leaders. Such information in KOMPAS-3D is called layout geometry. Next, 3D models of subassemblies are created, into which part of the layout geometry necessary for the design of a particular node is copied. Then, with the help of the LOTSMAN: PLM, calendar work schedules are formed, and specialists receive tasks for product development.

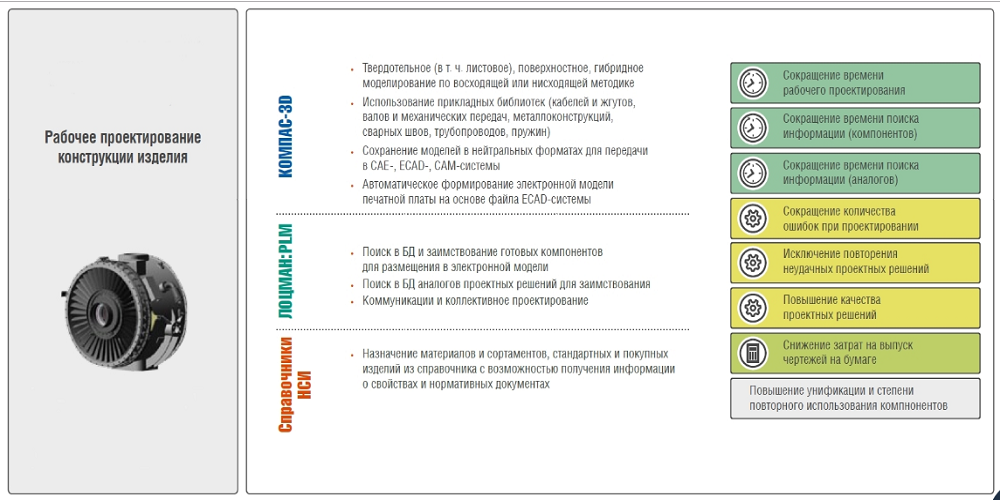

At the stage of detailed design, in the LOTSMAN product lifecycle management system: PLM the product composition is being worked out, calendar work schedules are being refined, and key design processes are automated. In KOMPAS-3D models of parts, assembly units and sets of design documentation are created.

At the same time, modern enterprises are often faced with the need to quickly study various product modifications in a short time. And here a very important function of the KOMPAS-3D system is the ability to form product versions, group specifications and drawings with execution tables.

In the context of an accelerated production cycle and an increase in the share of unique developments, the configuration management function in LOTSMAN: PLM is relevant. With its help, possible sets of parts and assembly units that can be used in the assembly of the final product, depending on the choice of the customer, are described. The configuration management functionality affects the consumer quality of products and is designed to solve priority tasks of custom production, quick layout from pre-compiled options, maximum convenience of order processing, and optimization of production preparation.

As a result of the stage of detailed product design in LOTSMAN: PLM, a constructive electronic composition is formed, which includes 3D models, drawings, specifications and other technical documentation.

The creation of the electronic structure of the product can take place in the LOTSMAN: PLM both manually and automatically on the basis of a 3D model obtained from a CAD system. PILOT: PLM by common standards interacts not only with CAD COMPASS-3D, but also with other three-dimensional modeling systems.

As part of the implementation at the enterprise, integration with Autodesk Inventor, CATIA, SolidWorks, Creo, Solid Edge, NX is possible. The interaction is carried out on the product tree and attribute information in the 3D model file, which in LOTSMAN: PLM act as the basis for the product composition containing drawings and other documentation.

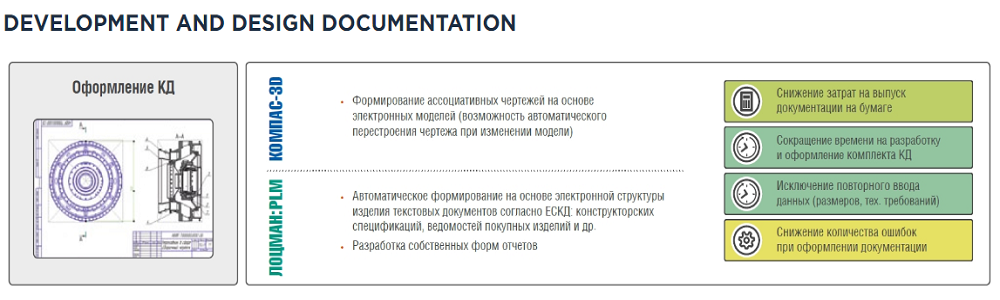

The structure of the ASCON solution includes tools to solve any problems in the preparation and execution of design documentation in accordance with ESKD. The development of documentation is based on associative connection with 3D-models. This technology completely automates the process and minimizes the number of errors in the documentation.

THE SOLUTION IS IMPLEMENTED ON THE BASIS OF PRODUCTS