UM Pneumatic Systems

Program package Universal Mechanism includes a specialized module UM Pneumatic Systems, which contains tools for simulation of models with pneumatic elements. The following elements are available in the current version of the module:

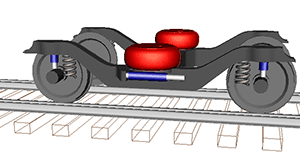

- Air springs

- Rigid chambers

- Pneumatic lines

- Orifices

The following AS models are available:

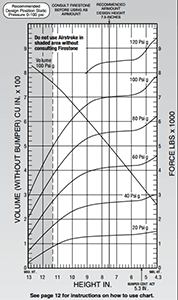

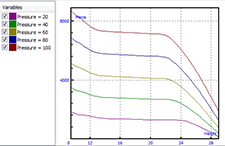

- Tabular model: the description of force element includes tabular experimental data on force and volume

- Nishimura model

- Berg model

- Thermodynamic model

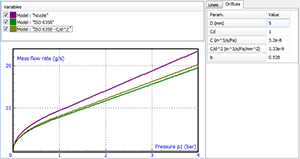

Orifice models

Orifice models

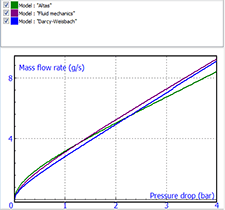

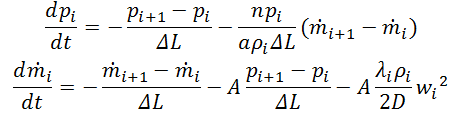

Similar to a pipeline, an orifice (nozzle, valve) is a connection between two nodes of pneumatic system. The mathematical model of an orifice includes a dependence of the mass flow rate on the pressure drop. The following orifice models are available in UM:

- Nozzle

- ISO 6358

Pneumatic systems

A pneumatic system in UM is considered as a graph, which nodes are connected by edges. Each node of a graph corresponds to one of the pneumatic elements:

- Rigid chamber

- Air spring (AS)

- Simple node

The graph edges are:

- Pneumatic lines

- Orifices

Verification tests

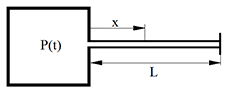

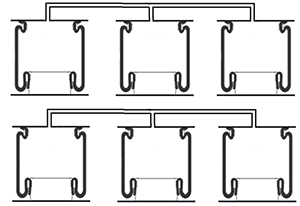

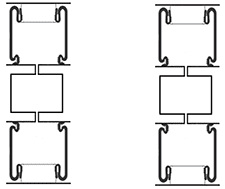

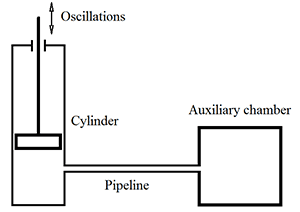

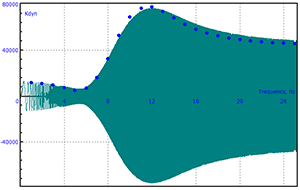

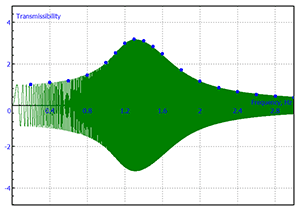

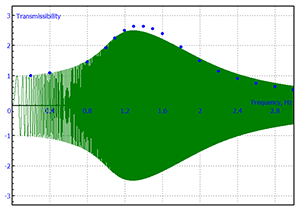

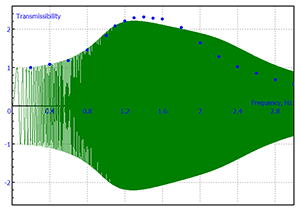

Case 1: Air spring connected by pipeline with auxiliary chamber

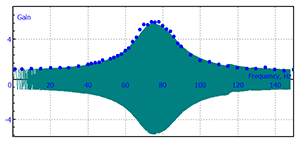

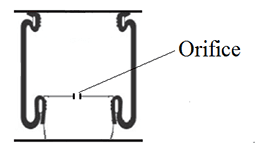

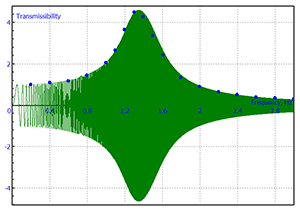

Case 2: AS connected by orifice with auxiliary chamber

Case 2: AS connected by orifice with auxiliary chamber

Case 2: AS connected by orifice with auxiliary chamber

Case 2: AS connected by orifice with auxiliary chamber

Case 2: AS connected by orifice with auxiliary chamber

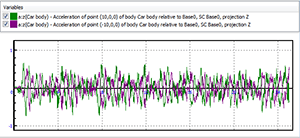

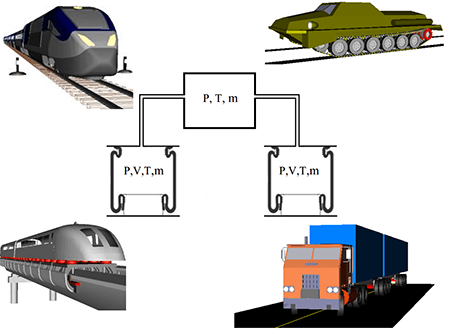

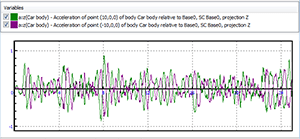

Simulation example: Heigh speed railway motor car