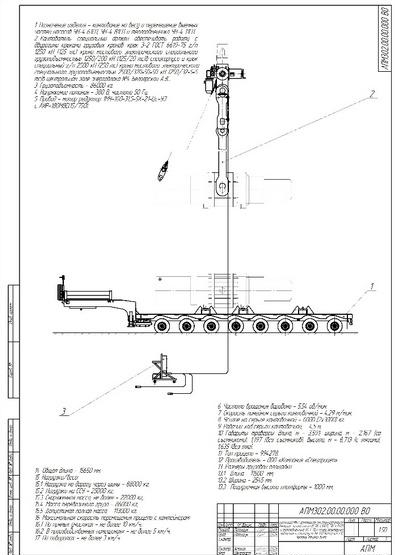

Special tilter device for transporting removable parts pumps VH 61SP-4, 4-81SP VH and VH-exchanger 4 11SP between the reactor compartment and special housing

introduction

Developing device spec with tilter for transporting removable parts pumps VH-4 61SP, VH-4 81SP and heat exchanger VH-4 11SP between the reactor compartment and special casing was performed STC "APM" by contract with "UfaAtomHimMash" and technical task UAHM .22.020.00.000TZ approved by the Chief engineer of the branch of JSC «Concern Rosenergoatom» «Beloyarsk nuclear power plant."

Purpose and area of application -tilting platform

Platform - tilter intended for raskantovki and transportation removable parts pumps VH-4 61SP, VH-4 81SP and heat exchanger VH-4 11SP with truncated upper part, installed in the transport containers at the export for repair special building and to deliver new or refurbished removable parts pumps VH-4 61SP, VH-4 81SP installed in shipping containers to a central hall (CH) №4 Beloyarskaya power plant.

Platform-tilter for KKS system (KraftwerkKennzeihenSystem) has 00SM01AE507 code.

Platform-tilter enables its use

at temperatures from minus 38 to (humidity 75%) to 28 about (humidity 50%).

Platform-tilter relate to seismic category III according to the classification of NP-031-01 "Standards of earthquake-resistant design of nuclear power plants", and 4 safety class in accordance with NP-001-15 "General safety situation of nuclear power plants."

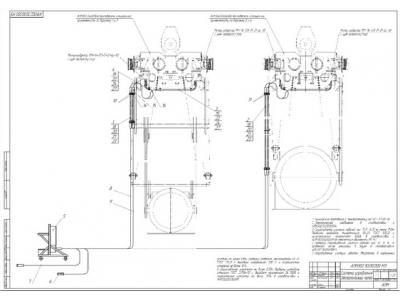

Platform-tilting device designed to work with double hook cargo cranes: GOST 6619-75 hook 3-2 g / p 1250 kN (125 tf) of the electric bridge crane special 1250/200 kN load capacity (125/20 n) in the special building and a special hook g / n 2500 kN (250 tf) of a special bridge crane lifting capacity electric 2500/320 + 50 + 50 kN (250/32 + 5 + 5 n) in the central hall unit № 4 Beloyarskaya plant.

Platform-tilting device incorporates a special tilter. For performing work on tilting containers on weight.

Platform-tilter provides together with the transport tractor removable parts pumps VH 61SP-4, 4-81SP VH and VH-exchanger 4 11SP with truncated upper part, installed in shipping containers by inland roads station ensuring the required radii trains reversal.

Specifications

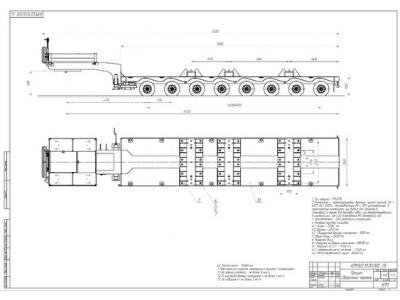

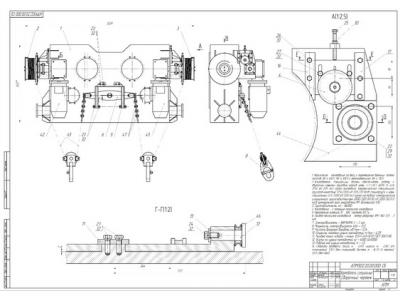

trailer type | 994278 | |

Manufacturer | "Company Spetspritsep" | |

Load: - on the road through the tires - on the tractor SSA | kg | 88000 25000 |

Weight: - Curb weight - weight of cargo - full mass | kg | 22000 86000 113000 |

Dimensions of the cargo area: - length - width - loading height platform - total length | mm | 11500 2545 1000 15650 |

The maximum speed of the trailer with cargo: - on the straights - indoor - cornering | km / h | 10 5 3 |

type of drive | electric | |

electric motor | AIR180M8E | |

motor power | kW | 15 |

Drum speed | rev / min | 5.54 |

Linear speed creasing earrings | m / min | 4.29 |

Traction rope winch | 13.5 G-1-H-1670 GOST 3067-88 | |

The force on the canting earring | kg | 6000 (2h3000) |

Stroke Creasing earrings | m | 4.5 |

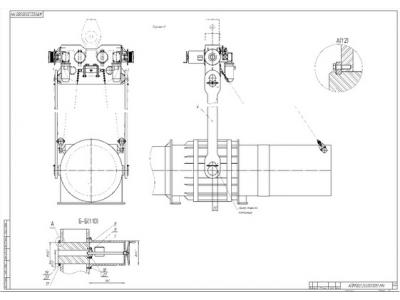

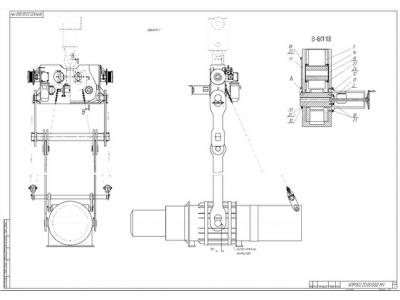

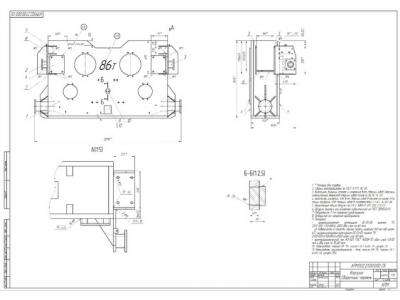

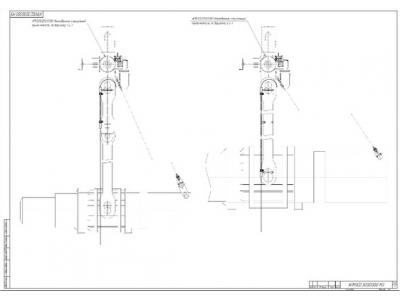

Dimensions of tilting special: - length - the width (w removers) - width (without puller) - height (with tie rods) - height (without links) | mm | 3591 2167 1197 8713 1635 |

Description of the construction

Special tilter device consists of the following elements:

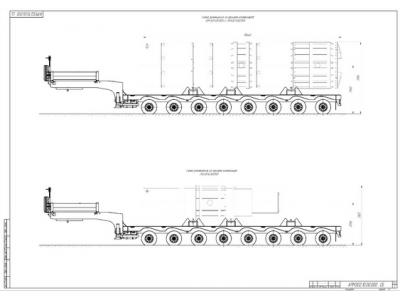

1. Eight-semitrailer special purpose hydraulically controlled axes provides the necessary turning radius when driving on roads inner station, the controlled axes can be rotated from a separate remote operator who can be located behind the trailer. This ensures accurate positioning of the trailer when reversing in confined spaces or when visibility for the driver is largely limited. cones for ranking special shipping containers.

three pillars mounted on the trailer. Each support is a box-like structure reinforced by gussets.

On supports installed centering cones for ranking special shipping containers.

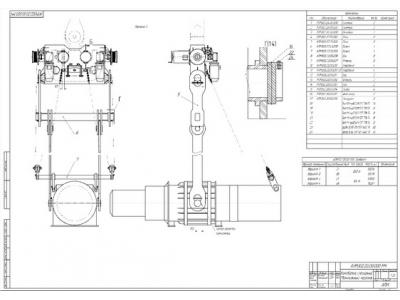

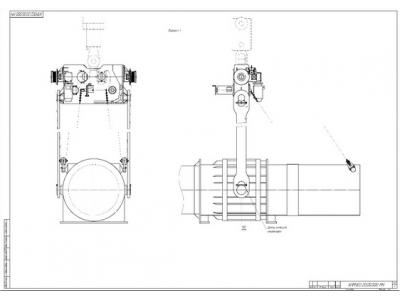

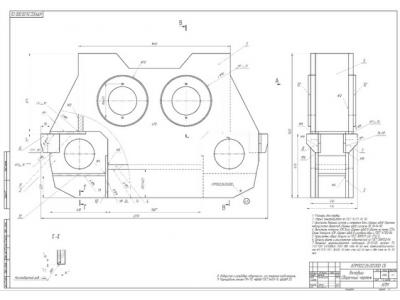

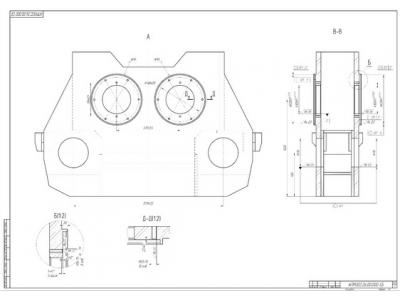

2. Tilter special designed to perform work on the tilting special containers with the load and provides operation with cranes 250 m and 125 m. Tilter consists of special baskets, designed to engage the crane hook, and the trunnion suspension for containers via rods and subsequent tilting containers via tilting mechanism arranged on a cart. Tilting mechanism comprises two mutually independent drive circuits, each of which includes a motor-reducer, the output shaft sprocket which is secured, for transmitting the rotation of the drum through a closed sprocket chain. Tensioning chain tensioner sprocket performed with the capability of forced vertical movement. The drum is mounted on the axle to rotate freely, with the axis fixed in the housing, fastening bracket located on an end wall of the basket.

the free end of the rope two coils are wound onto the drum from the side opposite the sprocket and fixed to the wall of the drum bolts through clamps. Further, after winding on the rope drum free end of the rope is passed via the unit earring Creasing and then through the thimble, after its fixation on the rope by clamping the group starts on the balancer shaft. Last mounted swingably about the axis on the side wall of the basket to angle limited staples.

The above-described scheme reeving rope from the drum to the rocker forms a double pulley block driven work own gearmotor. The closure of each of the ropes on the rocker edge equalizer circuit repeats the suspension of the elevator car, which provides equality of tension in each rope pulley circuit.

Special tilter has four options on the applicability that allows operation with two types of hooks and three types of containers.

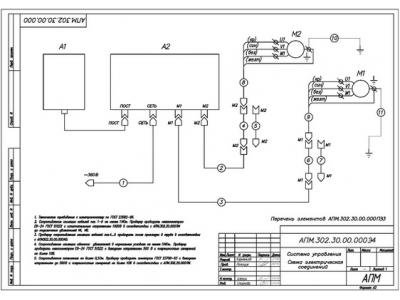

3. The control system provides on-off electric tilting mechanism, realizing the rotation of the drum and accordingly special tilting movement of the ropes, Kanto container. Driving organization management system provides a supply of electric power to the flexible cable, consisting of two circuits. The first circuit provides a fixed connection with the electric control box and further from said cabinet to the corresponding connectors on the connector block (a power cable is realized) and the communication control cabinet with a corresponding connector on the connector block (implemented cable control loop).

The second circuit includes a power cable communication from a corresponding connector on the block connector with the power cord, and the connection cable from the control circuit corresponding to the connector sockets with an external motor control unit.

conclusion

During the project execution design department has developed and delivered to the customer the next set of documents:

- TOR (based on the initial technical requirements);

- Technical project;

- Calculation of the strength of the main load-bearing structures;

- Set of design documentation;

- A set of normative and technical documentation, including:

- Program and testing methods;

- Passport;

- Manual;

- Repair manual.

At the moment, the product is developed at the manufacturing stage and preparations for the acceptance test.

After testing, this article will be updated and supplemented by photographs of the finished product.