PROJECT DIRECTIONS

- Automated development of technological processes for the manufacture of MSC products

- Production Technology Management

- Database of product design

PROCESSES

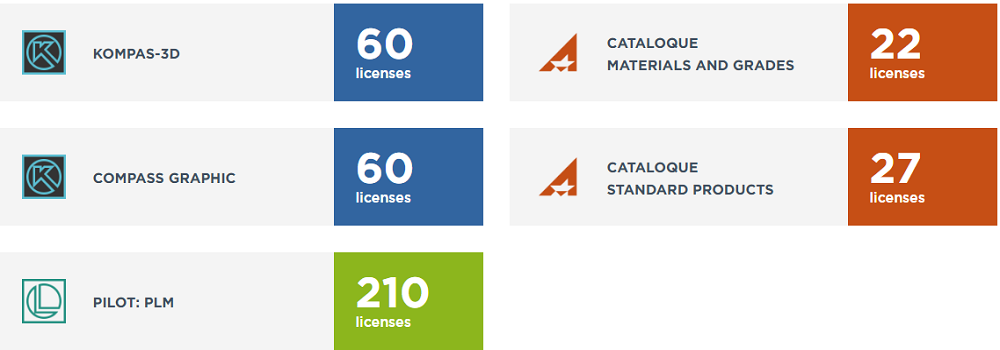

- Implementation of KOMPAS-3D

- Implementation of KOMPAS-Graph

- Implementation of the MiS directory

- Implementation of electronic document management system TD

- Implementation of electronic document management system TD

- Implementation of the electronic document management system CD

- Standardization of the process of developing TD

- Standardization of the CD development process

- Implementation of electronic document management system TD

- Implementation of the electronic document management system CD

- Implementation of the MiS directory

- Implementation of KOMPAS-3D

PROJECT DIRECTIONS

- Automation of design and technological preparation of production

- Engineering Data Management

- Reference Information Management

- Business process automation

- Integration with a production management system

PROCESSES

- DESIGN OF TECHNOLOGICAL EQUIPMENT, REFINING THE DESIGNER'S CD FOR THE PURPOSES OF MANUFACTURE

- CUTTING, FORMATION OF ORDERED SHIPPING, FORMING OF TECHNICAL KITS, DEVELOPMENT OF TECHNOLOGICAL PROCESSES

- FORMATION OF TECHNOLOGICAL AND NORMALIZING SHEETS

- FORMATION OF ORDERS IN PRODUCTION AND ACCOUNTING OF PERFORMED WORKS

- FORMING JOBS FOR CUTTING SHEET MATERIAL

- TRANSFER OF REGULATORY DATA IN THE AVPA MARS ERP SYSTEM

PROJECT RESULTS

Today Vympel Shipyard operates in a single information space - the construction of the computer network of the enterprise has been completed, covering all involved in the KTPP and production units of the enterprise.

PROCESSES

- DEVELOPMENT OF DESIGN, TECHNOLOGICAL AND DESIGN DOCUMENTATION

- STORAGE AND ACCOUNTING OF DOCUMENTATION

- AGREEMENT AND APPROVAL OF DOCUMENTATION

- DEVELOPMENT OF INTER-AHEAD TECHNOLOGICAL ROUTES

PROJECT DIRECTIONS

- Development and storage of design and technological documentation in electronic form

- Coordination of design and technology documentation for business processes

- Monitoring the status of development and technological preparation for the product

- Unification of developed and applied products

- Teamwork

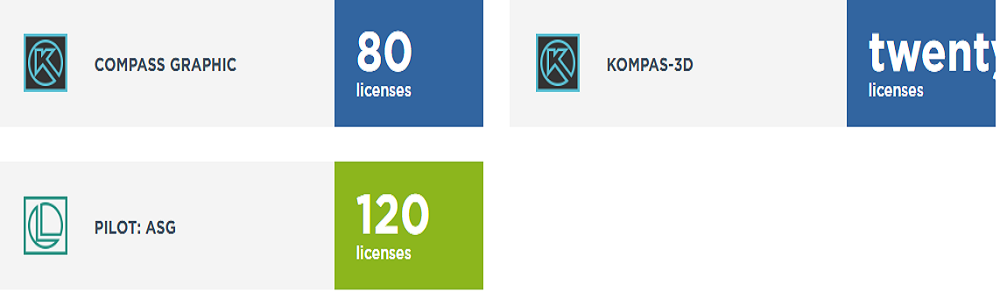

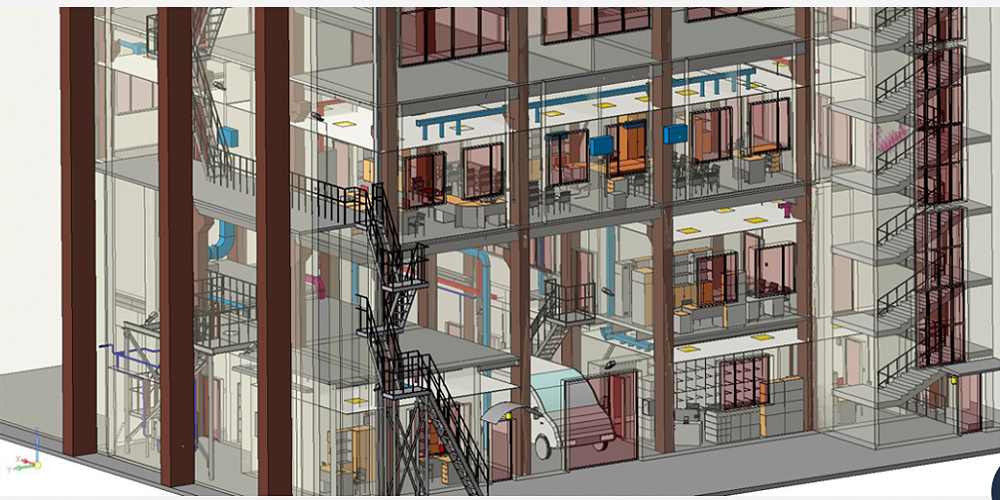

PROJECT DIRECTIONS

- Automation of planning and tracking the actual implementation of tasks;

- Automation of the creation, approval and approval of electronic documents using electronic digital signatures;

- Organization of collective work on the project, generation of a three-dimensional model of the building;

- Automation of changes;

- Automation of the issuance of internal technical tasks, the transition to paperless technology;

- Placing estimates in the structure of the project and transferring data on the estimated cost of the project to the ERP system;

- Connecting the customer to the archive of electronic documentation to gain access to up-to-date documentation, track the progress of the project, and automatically issue applications for copying documentation.

PROCESSES

- CREATION OF ELECTRONIC ARCHIVE PSD AND CD

- IMPLEMENTATION OF A PLANNING SYSTEM

- Creating dynamic samples of work for planning, planned work for the period in the context of the workshop, group, executor

- Receiving automated reports on planned and actually completed work in the context of workshop, group, executor

- INTRODUCTION OF THE ELECTRONIC DOCUMENT CIRCULATION SYSTEM

- CONNECTING THE CUSTOMER TO THE ARCHIVE

- INTRODUCTION OF DESIGN TECHNOLOGY

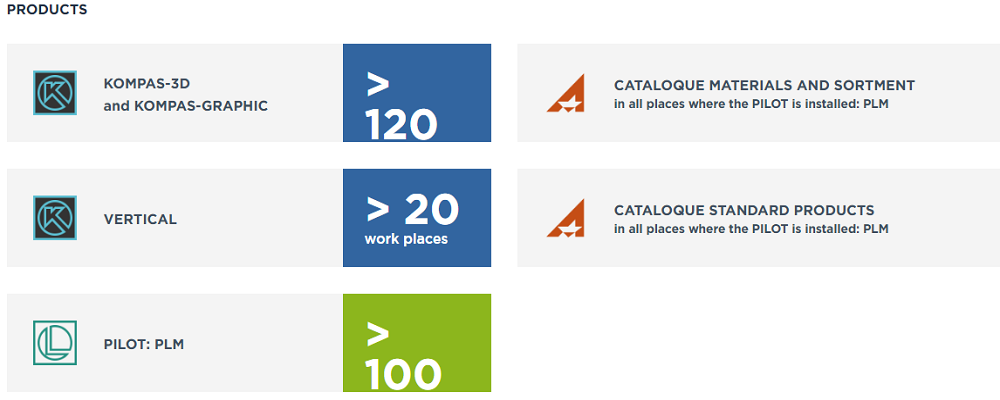

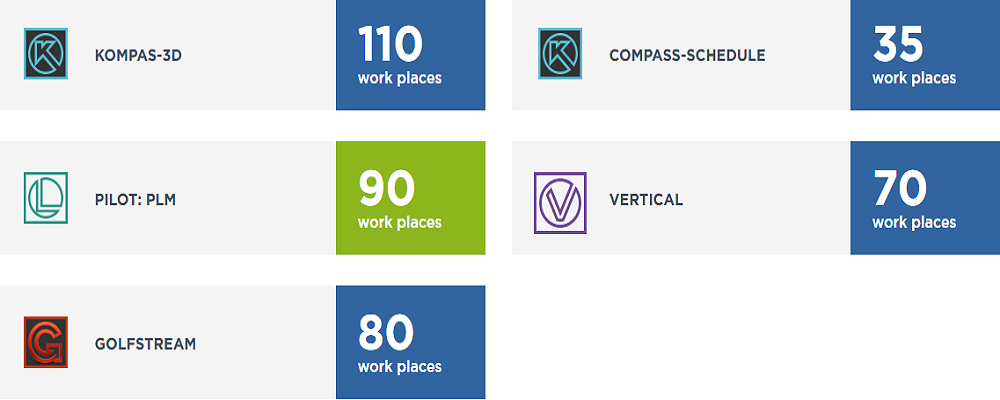

PROJECT DIRECTIONS

- design and technological preparation of production

- reference information

- process management

THE PROCESSES

- Design of parts and assembly units

- Creation and management of product structures

- Development and management of design documentation

- Development of technological processes and rationing

- Development and management of technological documentation

- Creation and maintenance of unified directories

- Order management

- Accounting for DSE movement in production

- In-shop management

- Production planning

PROJECT RESULTS

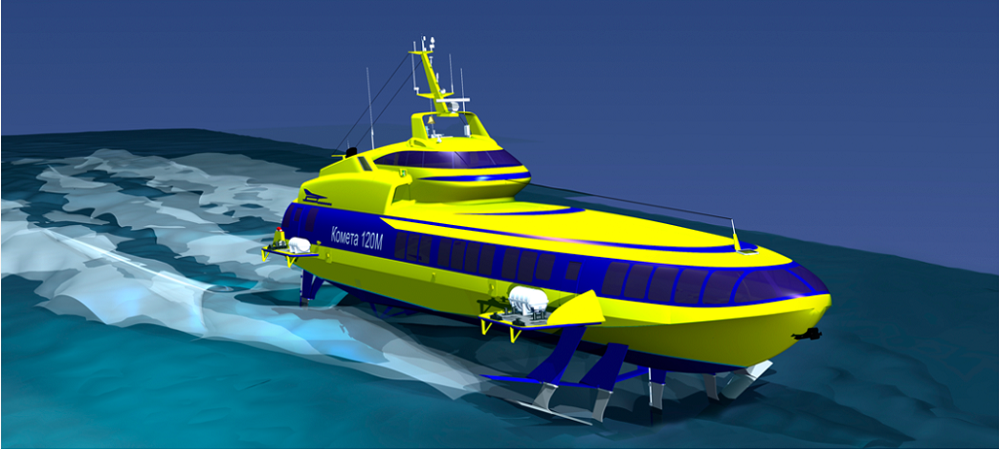

Today, the ASCON software package is integrated into the production processes of the plant. The GOLFSTREAM system contains data on the main products. The quality of information, its reliability, and the speed of receipt have improved. The movement of parts and assembly units along the routes is fixed, which gives all participants in business processes a complete and up-to-date idea of the production process. Implemented in-shop management, work orders are written out and closed in the system, and a mechanism for integration with the 1C: Enterprise accounting program has been established.

- Quality, accuracy and completeness of data

- Decrease in overproduction and stocks in work in progress

- Fulfillment of orders by the deadline

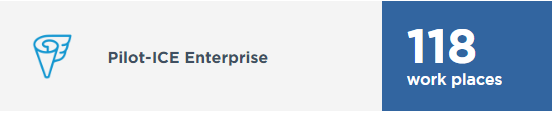

PROJECT DIRECTIONS

- Project Document Management

- Integration with a repair management system

PROJECT RESULTS

Integration of Pilot-ICE and 1C: MRO allows you to transfer almost any information from Pilot-ICE Enterprise directly to another information system, which is much faster and more convenient than through exchange file formats, for example, XML.

- 100% relevant information on projects for which construction and installation works are carried out

- Search through the server API for the attributes of objects allows you to work with more than 50,000 objects without loading the entire tree of objects

- Instant transition from object 1C to object Pilot-ICE