PASS/HYDROSYSTEM

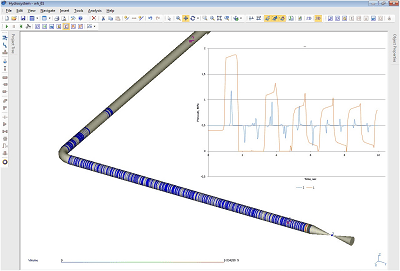

It also covers the most dangerous type of transitional flow related to liquid surge (water-hammer), and flow assurance calculations, including severe slugging, and gas hydrate formation prediction.

New employees can begin performing piping hydraulic and thermal analysis in days.

New employees can begin performing piping hydraulic and thermal analysis in days.

PASS/HYDROSYSTEM uses the most advanced models/algorithms and libraries for all level of simulation (both proprietary and from the most famous researchers/ developers from all over the world).

System RequirementsWindows 7/8/10+x86-64 architecture processor1GB of RAMVideo card with OpenGL 2.0+ support and 1GB+ of RAM Display resolution at least 1024x768, recommended 1280x1024

Overview

Overview

First introduced in 1977 and blessed by piping hydraulic world-known guru Idelchik, PASS/HYDROSYSTEM has since evolved into one of most powerful piping flow analysis tools.

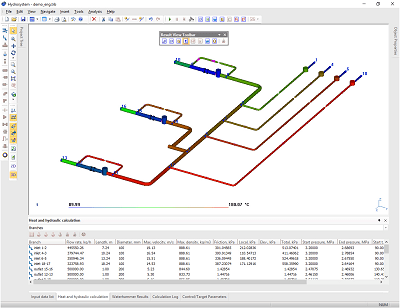

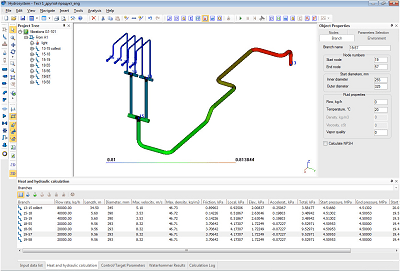

PASS/HYDROSYSTEM provides diameter selection, heat and hydraulic analysis of steady state flow for real liquids, gases, and multiphase mixtures (including gas/liquid, oil/water, and gas/oil/water flow considering flashing and condensation), in piping systems of any complexity, including networks with loops

PASS/HYDROSYSTEM combines sophisticated calculation capabilities with ease-of-use to deliver fluid flow and heat transfer simulation and sizing of any piping network in any design stage by “regular” engineers and designers. Process and piping engineers of more than 600 companies use the software now every day.

Pipelines analyzed include:

- Process piping systems at plants, storage facilities, pumping, and compressor stations;

- Plant utility piping systems such as steam, water, compressed air, inert gases, fuel, refrigerants, and others;

- Piping in mechanical industries such as aerospace, ship building, boiler, turbines, and more;

- Oil and gas upstream and midstream pipelines;

- Outdoor piping networks including district heating, water, and gas distribution;

- Other piping networks.

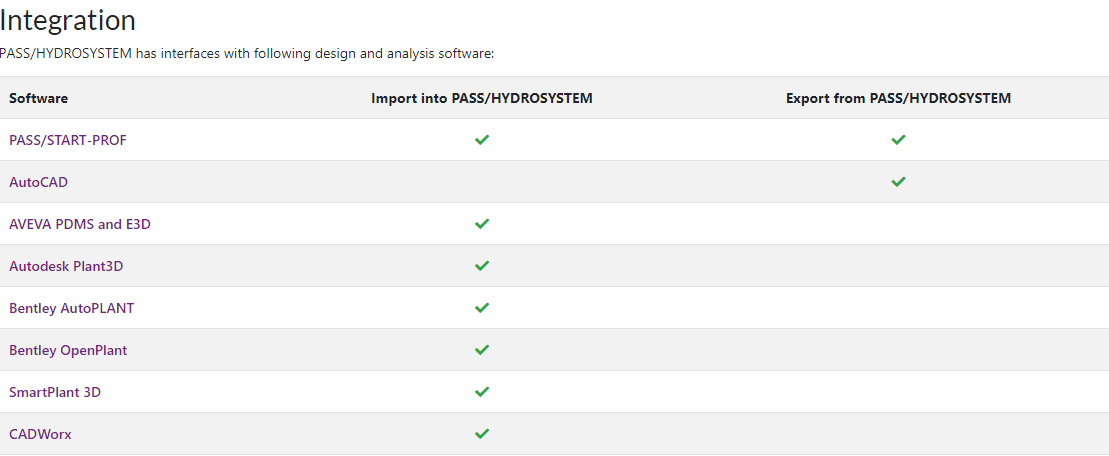

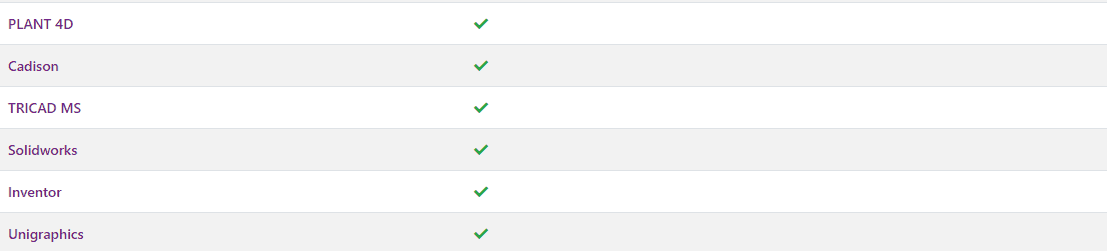

Extensive analysis capabilities, along with integration with popular CAD tools and within the PASS suite, makes PASS/HYDROSYSTEM an ideal component for any piping system design workflow

Features and Advantages

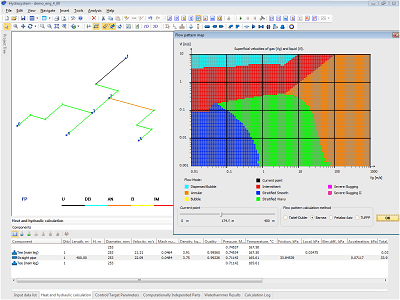

To analyze a piping system for hydraulic and thermal effects it is necessary to simulate its behavior on three scale levels: pipe cross section, pipe/branch run, and the whole piping network – and then link and solve these models together.

At the cross-sectional scale it is necessary to define the type of fluid flow (laminar, turbulent, choked, or subsonic, flow pattern for multiphase flow – stratified, annular, intermitted, etc.), and the specifics of heat exchange between fluid and environment through pipe wall and thermal insulation. This knowledge is then used when calculating integral parameters of the flow and heat exchange (pressure gradient, heat losses per length, etc.) and following up how all fluid parameters change along the pipe/branch and all over the network. This would be impossible without access to most reliable thermodynamic data provided by software.

PASS/HYDROSYSTEM provides a calculation engine for all necessary fluid properties and phase equilibrium on the base of fluid composition, for a wide spectrum of fluids and applications.

- The proprietary Properties library provides quick property calculation of ~150 most often used organic and non-organic components and their mixtures.

- The proprietary STARS library is focused on applications in the refining and petrochemical industry and allows for calculation of properties for individual fluid components, oil fractions and their mixtures in liquid and gas phases. This database contains more than 1600 components. STARS can also automatically compute gas-liquid phase equilibrium and check the validity of fluid phase entered.

- The GERG-2008 library allows calculation of natural gas thermodynamic properties and gas-liquid phase equilibrium based on the popular GERG-2008 equation of state.

- The WaterSteamPro module provides accurate calculations of water and steam fluid properties on the basis of IAPWS-IF97 equations.

For more advanced fluid properties and phase equilibrium calculations the program can use the Simulis Thermodynamics library by ProSim S.A.. This library covers Oil and Gas, Chemical, Biochemical, and other industries and provides a wide range of modern methods of physical properties, gas-liquid, and liquid-liquid phase equilibrium calculation for mixtures of more than 3000 compounds and oil fractions.

For hydrate formation prediction the program can use the Hydrate Open Structure module of the PVTSim library by Calsep, which can be purchased as a separate product.

This includes minor loss correlations by Idelchik, Miller, Ito; multiphase flow models by Chisholm, Friedel; drift-flux model, mechanistic models by Taitel, Barnea and Tulsa University Fluid Flow Project research group (with automatic closure relations selection); Todini Global Gradient Algorithm for network solver; Powell derivative-free method for optimization; and many others.

The program also calculates very complex networks with flow rate control elements and helps users analyze those networks with visual topology analysis features.

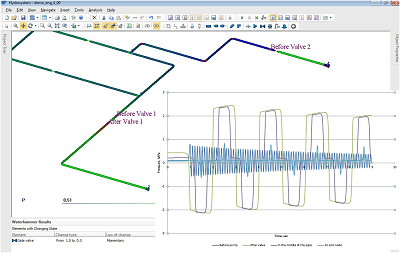

The PASS/ADD SURGE module implements the classical method of characteristics (MOC), using Riemann invariants and explicit numerical methods. It also considers possible cavitation during transitional flow, taking into account both, column separation effect and distributed vaporous cavitation.

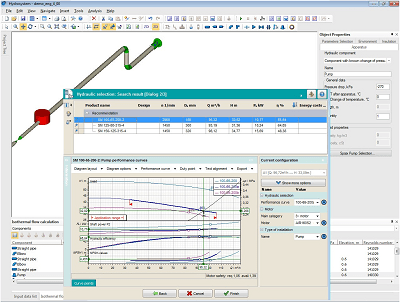

User interface

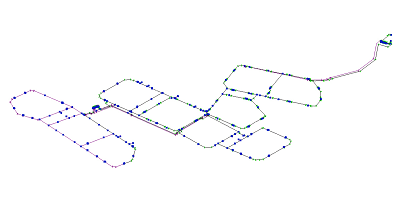

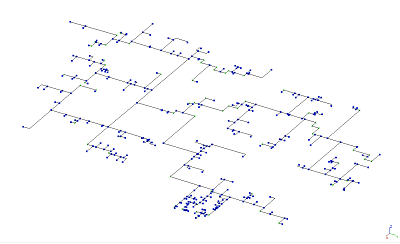

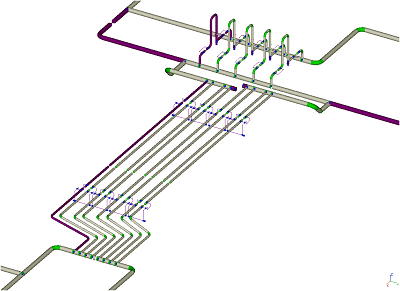

PASS/HYDROSYSTEM can work with a large spectrum of pipeline types on different stages of design and offers unique multi-variant graphical representations of the model. The program can switch between different modes and level of detail (PFD/P&ID – like unscaled scheme with regulated level of detailing, 2D scaled distributed networks on background map, and single line or solid 3D scaled, or unscaled representation for process piping) depending on what is suitable for a specific design phase and pipeline type.

The results can be viewed as color maps, animations (for surge calculation), easy-to-analyze tables, as well as user-customizable reports in PDF, MS Word, MS Excel, and other formats.

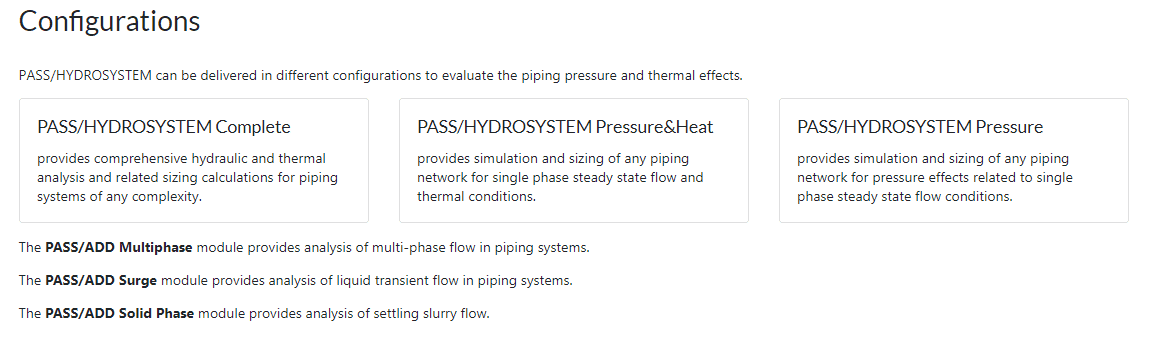

Configurations PASS/HYDROSYSTEM

Configurations PASS/HYDROSYSTEM