APM Mechanic

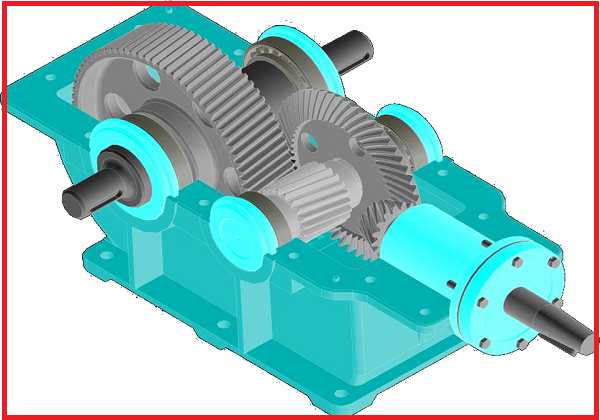

Russian CAE-system designed to perform design and verification calculations of machine parts and mechanisms.

Russian CAE-system designed to perform design and verification calculations of machine parts and mechanisms.

In fact, it is an integral part of the APM WinMachine software product , but it can function as a standalone one.

The product is capable of creating documentation in accordance with ESKD using databases of standard products and materials.

APM Mechanic is built on a modular basis, which makes it easy to use for narrowly focused industry tasks of mechanical engineering.

There are built relationships between the calculation modules to ensure the automation of the solution of complex problems, for example, the design of a reduction mechanism. In this case, the modules for the design of mechanica

transmissions, the calculation of shafts and bearings work in symbiosis. Information between them is transferred automatically. At the same time, the designer performs a supervisory function and, if necessary, can make adjustments at any stage of the calculation process.

All modules are divided into three thematic groups:

- Graphic tools (2D pre-post-processor);

- Machine parts and connections (calculations of typical machine parts, mechanisms, as well as their connections, both detachable and non-detachable);

- Databases (arrays of reference information in text and graphic forms on the parameters of materials, standard elements of mechanical engineering structures).

SOFTWARE CERTIFICATION PASSPORT 2019 This attestation passport establishes the purpose and scope of the APM Structure 3D software tool.

This attestation passport establishes the purpose and scope of the APM Structure 3D software tool.

SOFTWARE CERTIFICATION PASSPORT 2013 This attestation passport establishes the purpose and scope of the APM Structure 3D software tool.

This attestation passport establishes the purpose and scope of the APM Structure 3D software tool.

Working documentation

This section contains working documentation, namely installation instructions and user guides.

Up-to-date user guides are presented as separate documents for each module in APM Mechanic :

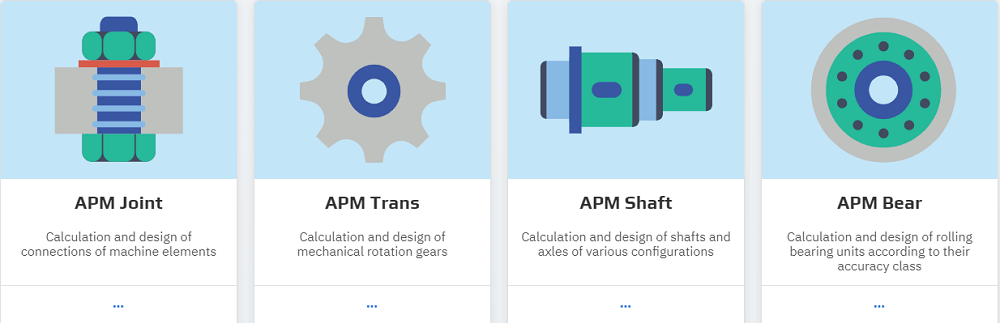

- APM Joint - module for calculating and designing connections of machine elements;

- APM Trans - module for calculating and designing mechanical transmissions of rotation;

- APM Shaft - module for calculating and designing shafts and axes;

- APM Bear - module for calculating and designing rolling bearing units taking into account their accuracy class;

- APM Drive - a module for computer-aided design of a rotary motion drive of an arbitrary structure;

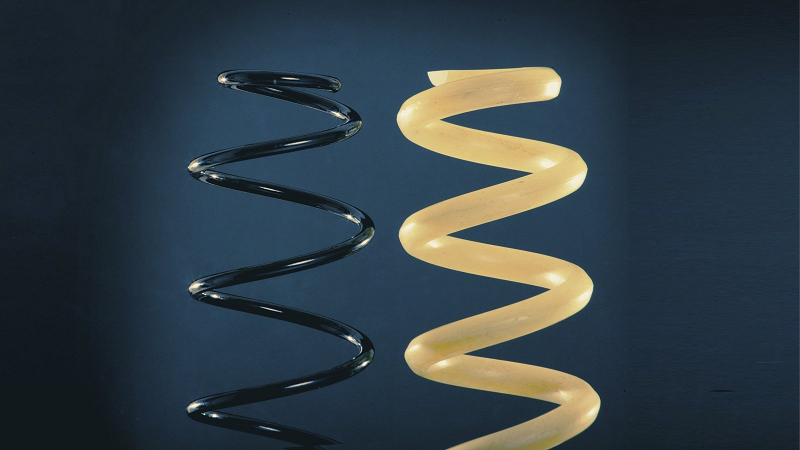

- APM Spring - a module for calculating and designing elastic elements of machines;

- APM Cam - module for calculating and designing cam mechanisms;

- APM Plain - module for calculating and designing sleeve bearings;

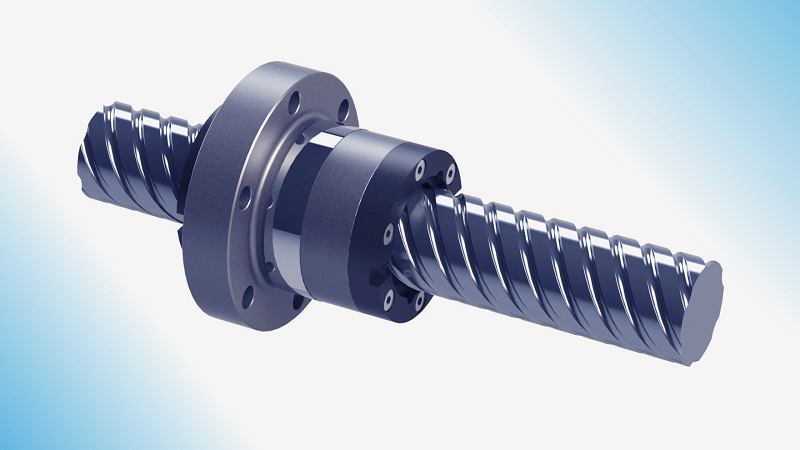

- APM Screw - module for calculating non-ideal screw drives (sliding, ball and planetary screw);

- APM Dynamics - module for kinematic analysis of linkage mechanisms;

- APM Graph - a flat parametric drawing and graphic editor with a tool for calculating dimensional chains;

- APM Base is a module for creating and editing databases.

Detailed installation instructions are described in the document.

Minimum hardware requirements:

- Two processors (cores) supporting 64-bit addressing.

- The amount of RAM is 4 GB.

- The amount of free space on the hard disk is 500 GB. A Radeon or Nvidia graphics card with hardware OpenGL support.

Hardware Requirements for Comfortable Operation:

- 4-core processor supporting 64-bit addressing.

- The amount of RAM is 12 GB.

- The size of free space on the hard disk is 1.5 TB.

- Video card with hardware support for OpenGL.

The best option for PC components:

- Two or more physical processors supporting 64-bit addressing.

- The amount of RAM - 32 GB and more.

- Radeon or Nvidia graphics card with hardware support for OpenGL.

- The presence of 3 physical disks:the 1st physical disk 1.5 TB is intended for the installation and operation of the OS;2nd physical disk 1.5 TB is designed for storing and recording calculation files;The 3rd physical disk 2.0 TB in RAID0 arrays is intended for writing / reading temporary files.

The software is designed for personal computers and runs in the operating environments MS Windows Server 2008, MS Windows Server 2012, MS Windows 8, 10

Russian CAE-system designed to perform design and verification calculations of machine parts and mechanisms.

In fact, it is an integral part of the APM WinMachine software product , but it can function as an independent one.

The product is able to create documentation in accordance with ESKD using databases of standard products and materials.

APM Mechanic is built according to a modular scheme, which provides the convenience of its use under highly targeted industrial tasks of mechanical engineering.

There are built interconnections between the computational modules to ensure the automation of solving complex problems, for example, designing a reduction mechanism. In this case, the modules for designing mechanical gears, calculating shafts and bearings work in symbiosis. Information

between them is transmitted automatically. At the same time, the designer performs the supervisory function and, if necessary, can make corrections at any stage of the calculation process.

All modules are divided into three thematic groups:

- Graphic tools (2D pre-post-processor);

- Machine parts and connections (calculations of standard machine parts, mechanisms, and also their connections, both detachable and non-detachable);

- Databases (arrays of reference information in text and graphic types on the parameters of materials, standard elements of engineering constructions).

Information about the software product APM Mechanic is prepared for registration in the Registry of Russian computer programs and databases .

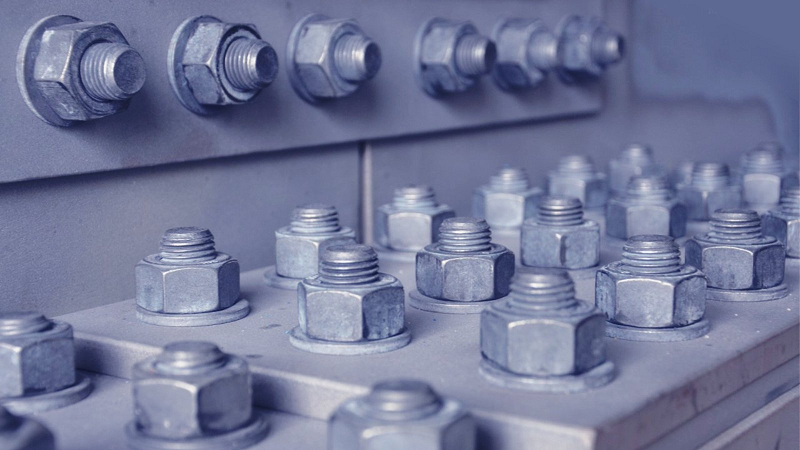

- welded various types;

- group threaded connections for all possible types of loading;

- riveted;

- connections of parts of rotation with tension;

- spline;

- keyways.

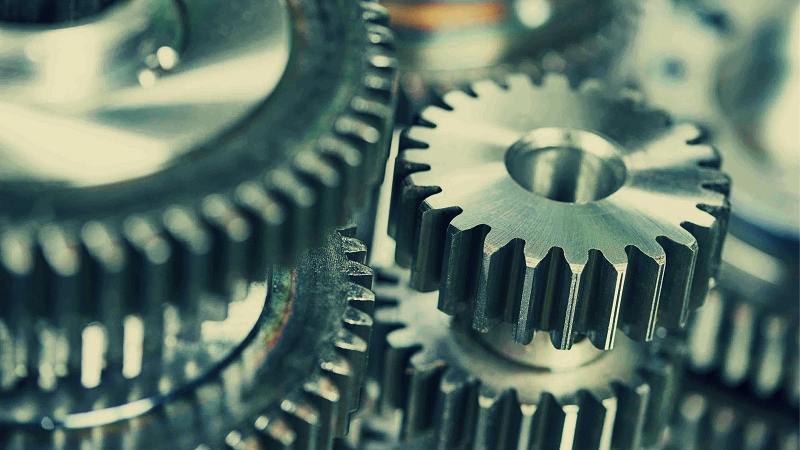

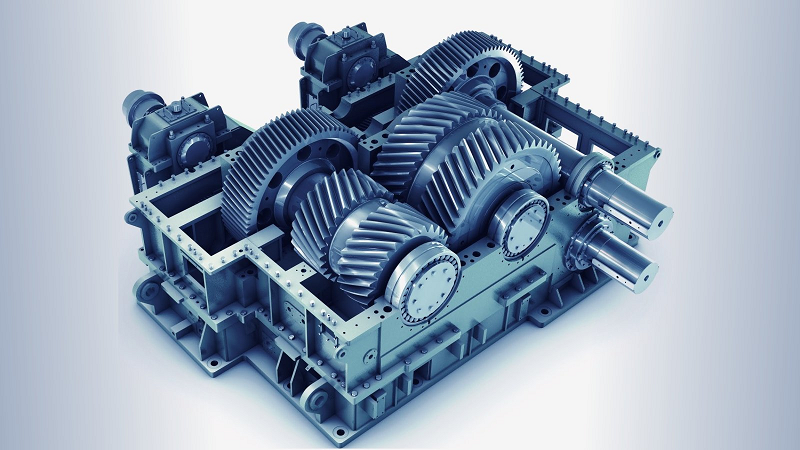

mechanical rotation gears:

- cylindrical gear external and internal gears;

- bevel gears with a straight and circular tooth;

- worm various modifications;

- various belt types;

- chain.

- static calculations;

- fatigue calculation;

- calculation of dynamic characteristics.

- gears with fixed axles (cylindrical, bevel, worm, belt and chain);

- planetary gears of various types.

- design;

- check.

- slip gears;

- ball screw gears;

- planetary – screw (roller – screw) gears.

- with progressive pushers;

- with beam pushers.

Calculation and design of machine parts and mechanisms (APM Mechanic)

The APM Mechanic will allows calculations based on the analytical relationships without the use of an approximate numerical analysis procedures. Since the procedure of calculation and design operate a large number of standard options, when creating complex software engineering analysis of the company SEC "APM" used data from national standards.

In a single environment CAE-analysis of the execution of calculations of mechanical transmission, machine parts and devices meets a set of programs called

the APM Mechanic will . The complex consists of a number of specialized programs.

With the APM Mechanic will, you can:

►Proektirovochny calculation and verification of the compounds (module the APM the Joint ):

- welded type;

- group of threaded connections for all possible types of load;

- rivet;

- connections with a tightness of parts rotation, splined, keyways, etc.

►Proektirovochny and checking calculation of mechanical transmission of rotation to give the full geometry of the transfer, the definition of tolerances and control parameters, and automatic generation of drawings transmission parts (module the APM of Trans ) . The calculation is performed for the transmission of rotation of the following types:

- spur internal and external links;

- bevel gear with straight and circular tooth;

- various modifications of the worm;

- belt type;

- chain.

►Proverochny calculation of shafts and axles (static and fatigue calculations, calculation of dynamic characteristics of the shaft), followed by visualization of the results in graphs and tables and automatic generation of drawing designed shaft ( the APM Shaft A ).

►Proektirovanie roller bearing units (module the APM of Bear ) and sliding (module the APM the Plain ) with the definition of the main operating parameters. The rigidity of the bearings and their components is calculated from the production of the bearing elements of the errors on the techniques developed by experts SEC "APM" and having no analogues in the world. Also the contact strength and rigidity during calculation and other parameters are defined by the bearing associated with its state of deformation.

►Proektirovanie drive rotational movement of any structure, including a transmission with fixed axles (cylindrical, conical, worm, belt and chain) and a planetary gear type (module the APM Drive ). Design completes the generation of drawings of individual parts and components and the creation of an assembly drawing.

Proektirovochny and checking calculation of the elastic elements of cars with subsequent automatic generation of elastic members DRAWINGS (module the APM Spring's ).

►Proverochny calculation of transmission of forward motion (sliding screw transmission, ball screws and planetary screw (roller screw) transmission). Calculation of ball screws and planetary-helical gears are performed according to the procedures developed in the company's SEC "APM" and having no analogues in the world (module the APM Screw ).

►Proektirovochny calculation and design of cam mechanisms with progressive rocker or pushers when an arbitrary law of motion changes, speed and acceleration of the pusher, with automatic generation of drawings of the cam profile (module the APM Cam ).

The composition of APM Mechanic:

| APM Graph - a flat parametric drawing and graphics editor with a tool for calculating dimensional chains |

| APM Joint - module for calculating and designing connections of machine elements |

| APM Trans is a module for calculating and designing mechanical rotation transmissions |

| APM Shaft - module for calculating and designing shafts and axes |

| APM Bear is a module for calculating and designing rolling bearing units, taking into account their accuracy class |

| APM Drive - automated design module for rotary motion of arbitrary structure |

| APM Spring - module for calculating and designing elastic elements of machines |

| APM Cam - module for calculating and designing cam mechanisms |

| APM Plain - module for calculating and designing sliding bearings |

| APM Screw - the module for calculating non-ideal helical gears (slip, ball and planetary-screw) |

| APM Dynamics - module for kinematic analysis of linkage mechanisms |

| APM Base - module for creating and editing databases |

| APM Mechanical Data - database of graphic information of standard parts and assemblies, reference data on engineering |

| APM Material Data - material parameters database |