PILOT: PLM

PILOT: PLM

PILOT: PLM helps you streamline workflows and devote more time to engineering and creating innovative products. Manage data and processes, work on collaborative projects and quickly find the information you need.

PILOT: PLM allows you to manage data and processes, organize the teamwork of specialists and quickly find the information you need. Using the PILOT: PLM will help you streamline your workflows and devote more time to engineering and creating innovative products.

PILOT: PLM is a software platform that allows you to create information systems for managing product data taking into account the specifics of any machine-building enterprise, as well as a set of application modules that provide solutions to typical, standardized tasks in specific areas.

The basic functions of the LOTSMAN: PLM software platform are

- storage management of data and documents

- product structure and configuration management

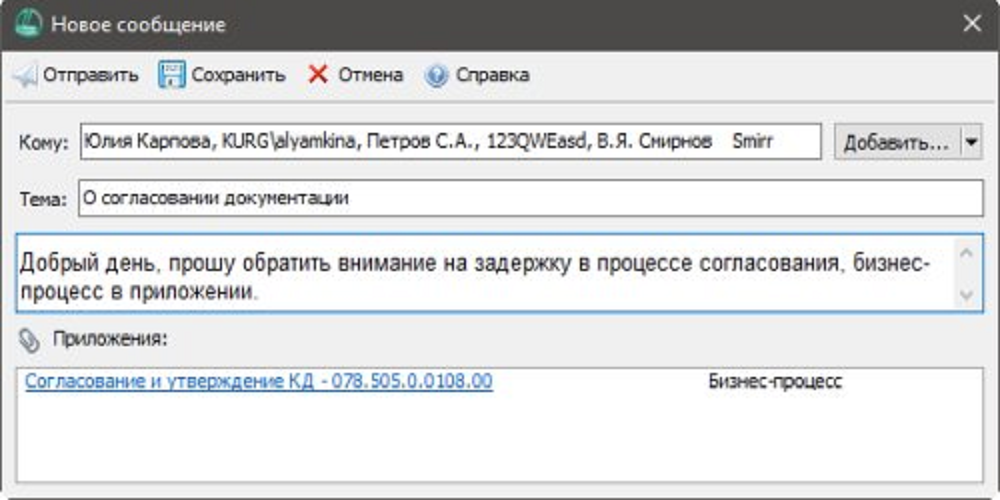

- communication management and messaging

- integration with CAD and other software tools

- scheduling and project management

- process management (WorkFlow)

- reporting

Pilot modules: PLM allow you to solve problems in such subject areas as technological preparation of production, change management of design and technological documentation, archival accounting of technical documentation, as well as solve other specific problems.

API and SDK development tools, as well as business configuration and administration tools, allow you to configure and scale the LOTSMAN: PLM system in accordance with various enterprise requirements.

STORAGE MANAGEMENT OF DATA AND DOCUMENTS

LOTMAN product data: PLM is a collection of interconnected information objects having a set of attributes and files describing properties (characteristics), design, manufacturing technology and other information about the product at a certain stage of its life cycle. A complete set of such interconnected information objects describing the product forms an electronic description of the product.

In addition to organizing product data in LOTSMAN: PLM, there are mechanisms that allow you to keep records of documents in various presentation forms (in electronic form, on paper) on various media (paper, files on storage devices) stored or in use, to ensure necessary documents of subscribers (production, engineering services, external contractors) and keep subscriber records.

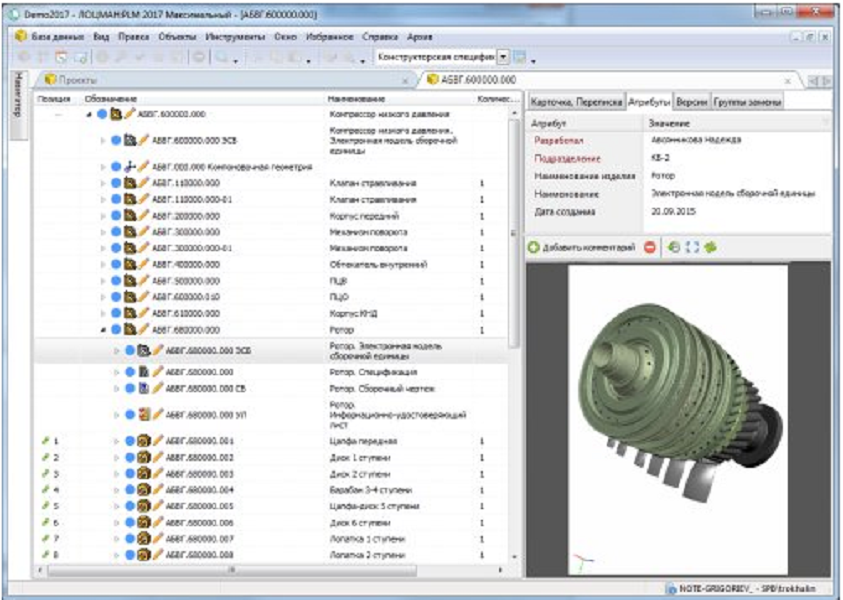

PRODUCT STRUCTURE AND CONFIGURATION MANAGEMENT

The structural basic electronic description of the product in LOTSMAN: PLM is the electronic structure of the product (ESI) - a hierarchically related set of information objects of various types, depending on the type of ESI. For example, the constructive electronic structure of the product is represented by such elements as assembly units, complexes, parts, standard and other products, sets. Technological ESI can additionally include technological assemblies, with the help of which the components are structured in one way or another, taking into account the peculiarities of the manufacture of the product (for example, the assembly sequence).

The formation of ESI is possible both by creating information objects by the user in the LOTSMAN: PLM interface, and by automatically creating them based on information from CAD document files.

Configuration management mechanisms in LOTSMAN: PLM allow you to create multivariate product structures, eliminating the need to describe each option in full, instead describing only the differences (options, replacements, options). In the standards of the ESKD series, a similar role is played by executions and production and technological options for manufacturing products. PILOT: PLM provides support for executions and production and technological options (the so-called “permissible replacements”), taking into account all the requirements for their entry in derivatives (design specifications, statements, etc.).

INTEGRATION WITH CAD AND OTHER SOFTWARE

Universal Pilot Integration Mechanism: PLM allows you to interact not only with KOMPAS-3D, VERTICAL and other ASCON products, but also with various third-party solutions. The base delivery contains modules for integration with SolidWorks and AutoCAD. Within the framework of the implementation project, integration with CAD systems such as Inventor, CATIA, Creo, NX, Solid Edge is possible. Interaction with EDA solutions Altium Designer, Delta Design is supported.

The closest integration is implemented for ASCON tool programs: KOMPAS-3D and VERTICAL. In these bundles, information exchange mechanisms are implemented taking into account various requirements of domestic standards (ESKD, ESTD). For example, in the integration links between the LOTSMAN: PLM and such documents as the design specification, assembly drawing, electronic model of the assembly unit, the ESKD requirements for positioning, designing zones on drawings, recording data in various sections of the specification, recording acceptable substitutions and substitute materials are taken into account. These requirements are taken into account in such a way that the user does not need to re-enter data in different documents and in the LOTSMAN: PLM.

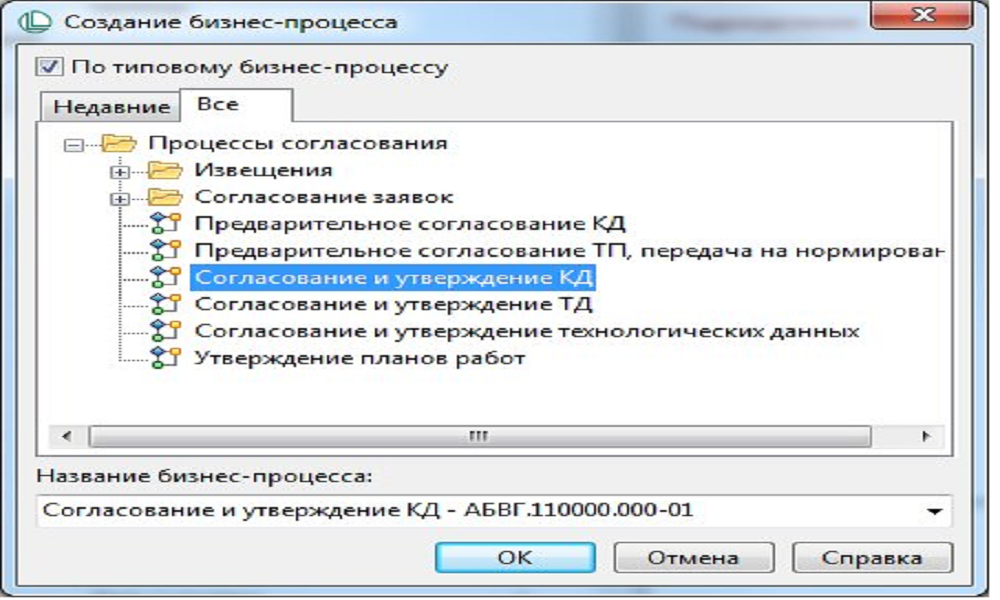

PROCESS MANAGEMENT (WORKFLOW)

The specialized LOTSMAN WorkFlow module, designed to manage the enterprise’s business processes, allows each participant to receive initial data, record the results of their work and transfer tasks to other process participants, and managers get the opportunity to monitor the work and automatically receive notifications of violation of deadlines.

The most common application for the process control subsystem is the approval and approval of documents and data. To support the approval procedures in the LOTSMAN: PLM built-in electronic signature mechanisms (both simple and enhanced). During the verification of the document, the coordinator can, without opening the document in the tool (for example, the CAD system), view its contents in the special secondary presentation workspace. At the secondary presentation, you can not only view documents, but also perform text and graphic annotations, fixing your comments on the contents and design of the document.

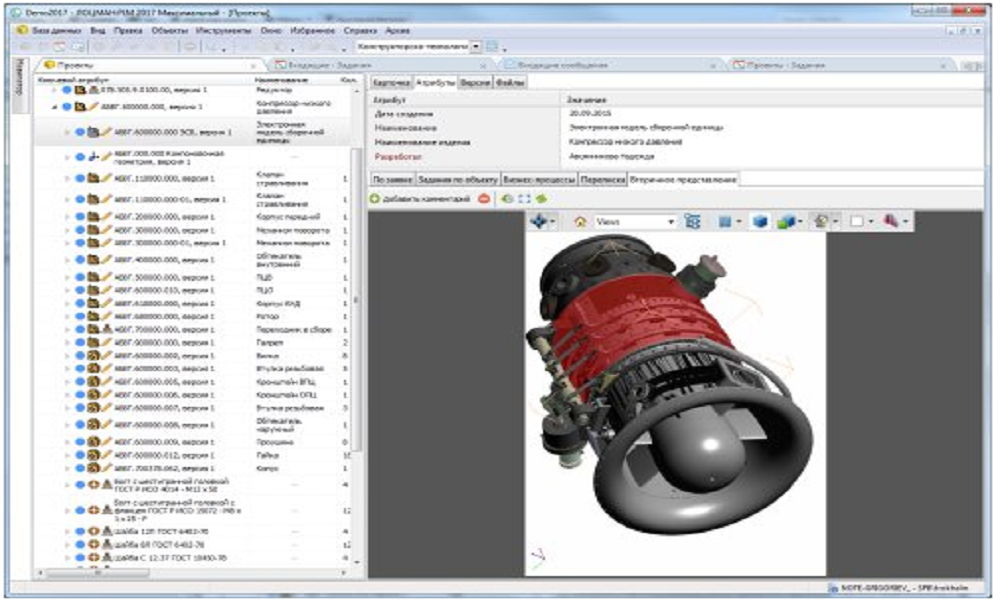

SCHEDULING AND PROJECT MANAGEMENT

Engineering processes require planning and monitoring on an ongoing basis.

Pilot functional: PLM allows you to plan and track the implementation of both individual tasks and their aggregates, organized in work plans at the level of individual specialists, departments, departments and the whole organization. The system allows you to create a plan in the form of a structure of interrelated work, to connect tasks with each other, set planned deadlines, assign performers, and priorities. The display of the work plan is possible both in tabular form and in the form of a Gantt chart. After creating a work plan, the system will help to identify various planning conflicts, for example, related to the excess of the planned load over the available amount of resources

COMMUNICATION AND MESSAGING

The messaging subsystem allows specialists to exchange messages containing links to objects and documents within the system, significantly accelerating the communication of specialists.

REPORTING

PILOT: PLM allows you to generate reports in office suite formats (Microsoft Office, OpenOffice), as well as using the FastReport report generator. Specialists of the enterprise can independently, or with the help of an integrator, implement any logic for selecting data for output to reports using scripts, configure arbitrary templates (forms) of reports in accordance with the requirements of enterprise standards. The most common standardized reports in accordance with the requirements of the ESKD and ESTD series standards are delivered ready-made (for example, design specification, list of purchased products, list of materials, etc.).

Applications:

Version: Windows 7 and later

Edition: Professional and higher

Bit depth: x32 / x64

Pilot pilot part: PLM:

Version: Windows Server 2008 R2 SP1 and later

Edition: Standard and higher

Bit size: x64

Trade In Substitution

DO YOU WANT TO AVOID THE RISK OF UNAUTHORIZED ACCESS TO DATA, BUT USE UNAPPROVED SOFTWARE? ARE YOU AFRAID OF DISCONNECTING FROM THE SUPPORT OF IMPORTED SOFTWARE AMID A WORSENING POLITICAL SITUATION? ARE YOU PLANNING TO FOLLOW THE COURSE OF IMPORT INDEPENDENCE, BUT HAVE NO IDEA WHAT TO DO WITH ALREADY ACQUIRED CAD AND PLM?

ASCON will help to take the first step towards import substitution using the Trade-in. Substitution ": we will take into account your investments and replace the licensed CAD or PDM / PLM of a foreign manufacturer with powerful and secure systems KOMPAS-3D / KOMPAS-Graph, LOTSMAN: PLM, CAD TP VERTICAL.

In 2014, KOMPAS-3D, CAD TP VERTICAL and LOTSMAN: PLM confirmed the status of protected software products by receiving certificates of the Federal Service for Technical and Export Control (FSTEC of Russia) for operation in the “For official use” circuit.

SPECIAL OFFER TO PROGRAM PARTICIPANTS

| Discount | |

| KOMPAS-3D | 65% of the standard price KOMPAS-3D |

| KOMPAS-Graph | 65% of the standard price KOMPAS-Graph |

| PILOT: PLM | 60% of the standard price PILOT: PLM |

| VERTICAL | 60% of the standard price VERTICAL |

| PILOT: KB | 60% of the standard price of the PILOT: KB |

Terms of participation in the Trade-in. Substitution ":

- The program applies to licensed users of any foreign computer-aided design (CAD) systems released earlier than 2017.

- All workplaces of the KOMPAS-3D, KOMPAS-Graph, LOTSMAN: PLM, VERTICAL systems purchased under the program are subject to the standard terms of technical support and updates. Applications for systems are purchased at a list price.

- Confirmation of the license cleanliness of the replaced software is a copy of the license agreement and software license numbers.

- Confirmation of the refusal to use the replaced software is the official letter of the organization.

Participate in the Trade-in. Substitution ":

be sure of safety - go to ours!

To participate in the KOMPAS program, fill out the application and send it to: tradein@ascon.ru or fax (812) 703-39-30 , 703-39-34 .

To participate in the Pilot Program: PLM and VERTICAL, fill out the application and send it to the address: complex@ascon.ru or by fax (812) 703-39-30 , 703-39-34 .