5 Axis Continuous

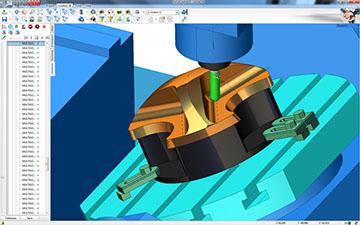

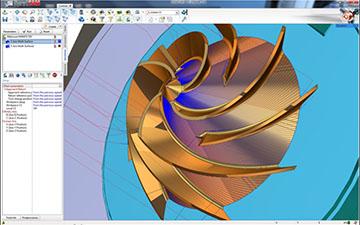

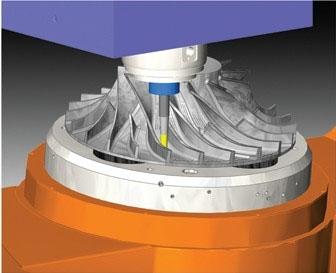

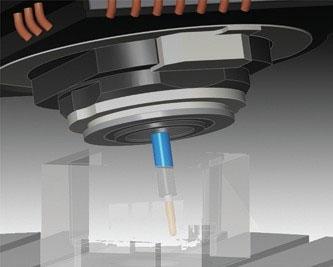

SprutCAM has 5 axis continuous strategies, which enables to create CLData for any type of multiaxis machines. The CLData is created taking into consideration the machine scheme, which permits to avoid collisions during the machining. The CLData is created taking into consideration the transformation of the co-ordinates of the machining.

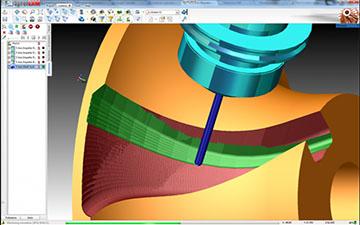

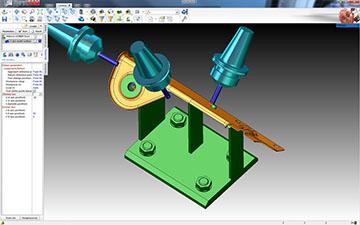

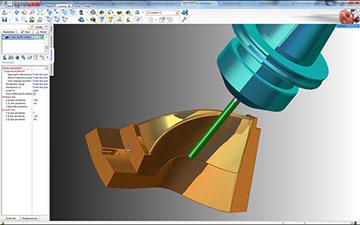

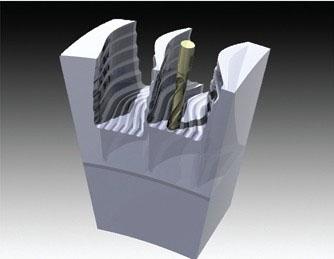

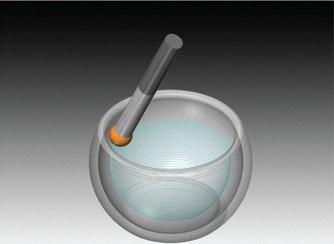

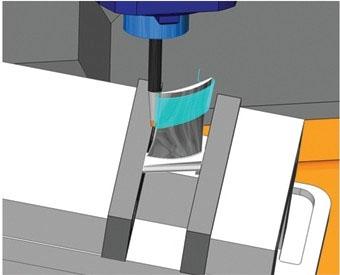

n the process of continuous five-axis machining simultaneous movement along all of the five axes of the machine may take place. The key feature of this type of machining is that along with the control strategies of the cutter movement over the surface of the part, strategies of tool axis orientation control are used. Strategies of the tool motion over the surface of the machined part are well known, these are, for example, layer rough sampling of material, finishing motions providing constancy of the height of the ridge, motions along the defined curves on the surface, between the curves on the surface, between the check surfaces, etc. However axis orientation control strategies are the methods, allowing to change the tilting of the tool axis during machining according to the certain fixed rules. The simplest way from programming viewpoint is the orientation of the cutter axis normally to the working surface. This method has a number of disadvantages, for example, the path often falls outside the axes movement range, it is also impossible to machine the interiors of the part, the life of the cutter is short because the cutting point is located in the small cutter area, finally, cutting speed in the axial cutter area is much lower than in the outside area. And beside that in case of using such a processing method it is difficult to take into account the presence of fixturing, tool holder geometry, to bypass nonmachining forms of the part. To resolve these problems SprutCAM uses various strategies of cutter orientation control relative to the work part surface.

Strategies for generation of the tool-path over the surface of the part

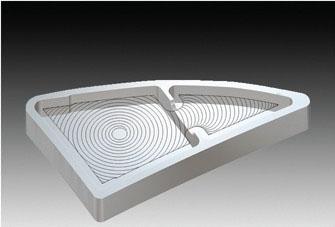

Rough layer sampling, rough plunger sampling.Finishing with the defined step, finishing supporting the constancy of the height of the ridge between the cuts and stream finishing.

One way as well as zigzag spiral tool motions.

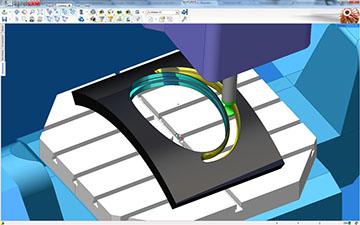

Generation of the tool-path between the guide curves.

Five-axis machining along the contour along the edge of the part.

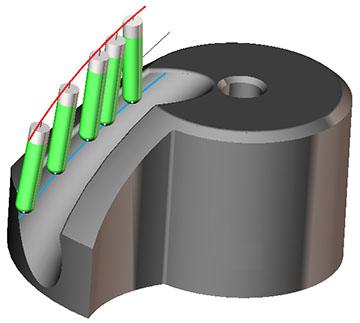

Machining of the ruled angled surfaces by the sidepiece of the cutter.

Transformation of measuring machine data into the geometry.

Strategies of tool axis control

Independent definitions of the angle of the axial tilt sideways and in the direction of the tool movement.Orientation of the cutter through point to the surface, through surface to the point, through curve to the surface, through surface to the curve.

Control of the tool movement between the defined angles and maintenance of the specified tilt that does not affect the part process and does not exceed the limits of the machine.

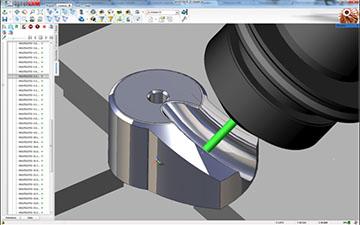

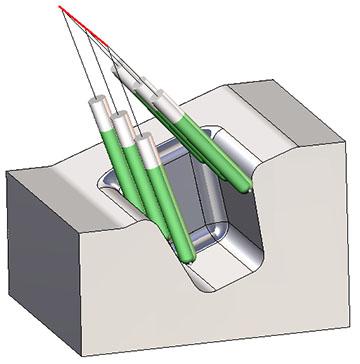

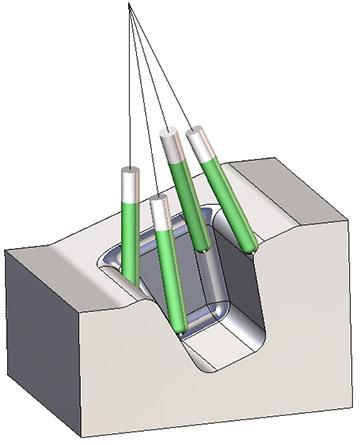

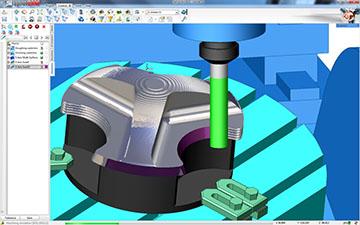

Control of the minimum angle of the tool inclination is helpful in avoidance of motions, which may cause holder-to-part collision.

Collision avoidance function automatically changes the tool axis direction before the collision. The system tilts the cutter from the obstacle to the defined distance and after the obstacle is passed, it returns the milling angle to the value specified for the whole path.