Rotary Machining

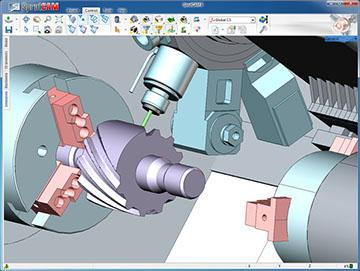

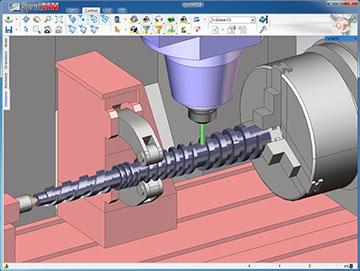

Rotary machining is intended for obtaining the polysurfaces of the parts such as turbine blades, shoulder blades, screws as well as the details like camshafts and crankshafts. It has widespread application in the Aircraft, Automobile, Petroleum and Gas Industry and also in the process of manufacturing of decorative figures and other complex parts.

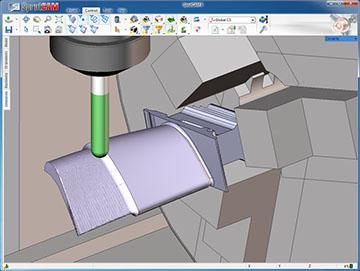

SprutCAM has a wide range of parameters for the rotary machining operation and enables to get all the types of the parts listed above taking into account the specific characters of the production works and availability of the equipment (numerical control milling machines with the capability of three-axis operation and having at least one continuous rotation axis or the turn-milling machines with the power-driven tool).

The key feature of the operation is that along with the linear axes mainly only the fourth rotation axis appears to be involved with the fifth axis being fixed (if it is present). In some cases the fifth axis of the machine may also be used.

Main technological parameters of the operation:

Calculation of the path with the use of the rough cuts - Spiral, linear or circular path generation - Calculation of the tool contact point with account of the defined position of the tool axis - normally to the surface in every point, normally to the rotation axis. - Definition of the deflection angle from the selected type of the position of the tool axis normalGeneration of the tool path of both the groups of surfaces and separate surfaces and elements, as well as the entire part.

In SprutCAM the path is calculated with account of the equipment layout, performed in the form of 3D model and the process of calculation takes into consideration such equipment parameters as the movement range of the working parts and their contact among themselves, which allows to completely control the motions. In these circumstances, the gouge check is used to control the part and the additional objects (various clamp straps and devices) whose models are placed into the list titled «Equipment».

A work piece may be defined in the form of a block, a cylinder, a rotation body with the permanent allowance or of the prismatic form as the remaining material after machining by upstream operations, and also in the form of a free geometric model, consisting of solid bodies, surfaces and grids.