Turn-Milling

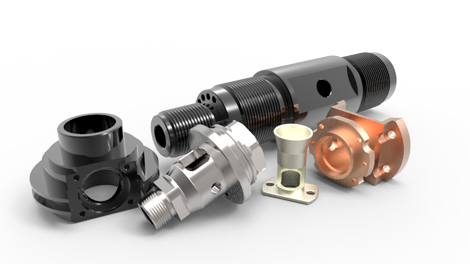

Turn-Mill module of SprutCAM includes powerful turn-milling methods to program multi axial machining with support Multi-tasking Turn-Milling centers with live tooling, include CNC Swiss-Type Lathe. Easy interface and features of the lathe module the ability to program roughing, finishing, grooving, threading and part-off machining operations.

The turn mill machining is a machining of a part on a turn mill machine, when after the part has been fixed once, there can be done turning and milling operations.

Control of all the machine mechanisms

Turning operations

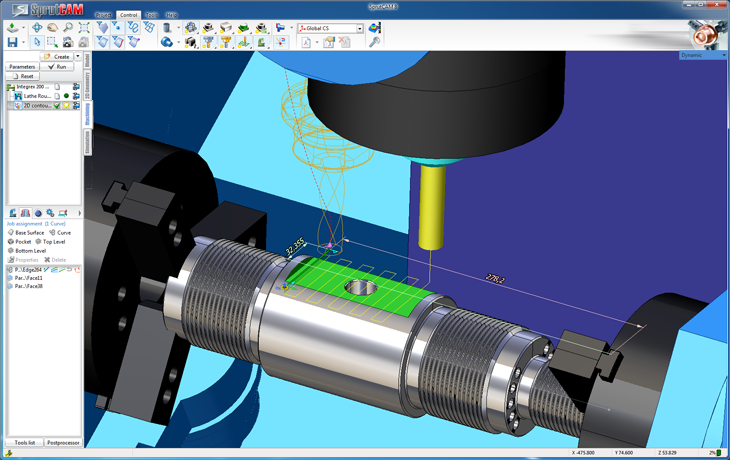

SprutCAM offers a wide variety of turning, boring, drilling strategies, including: rough turning cycles, finishing cycles, grooving cycles, all types of chasing cycles on cylindrical as well as conic surfaces, turning of screw surfaces of any section with permanent and alternating step, holes machining cycles using tools from the leading manufacturers as well as specialized tool made in house. In order to achieve an optimal machining of parts using B axis, the user is given a convenient mechanism of control of the cutter tilting angle relative to the part’s surface.

Milling operations

All types of rough and finish milling used with regular milling machines are supported.

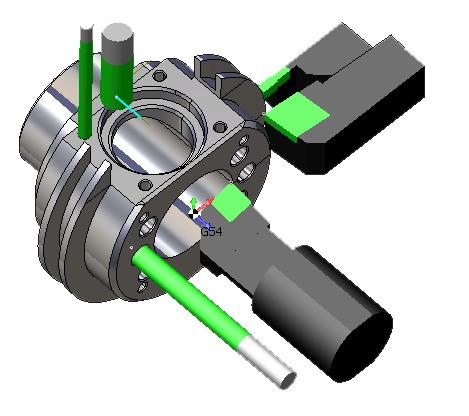

SprutCAM permits to create NC programs using C and Y axis for machining with the main spindle as well as with the sub spindle, in the outer diameter of the part as well as on its end surface. If the machine is equipped with B axis, then the index milling machining of the part is supported in tilted planes, as well as the simultaneous 5 axis machining using all the machine’s axes.

When the machine does not have a Y axis, then in order to machine a part’s end surface, SprutCAM permits to make the NC program in the polar coordinates. Moreover, if the machine has embedded functions for recalculations from the Cartesian into the polar coordinates, SprutCAM includes all the necessary commands in the NC program.

In order to carry out milling on a cylindrical surface using a continuous movement along the C axis, the cylindrical coordinate system can be used.

Auxiliary operations

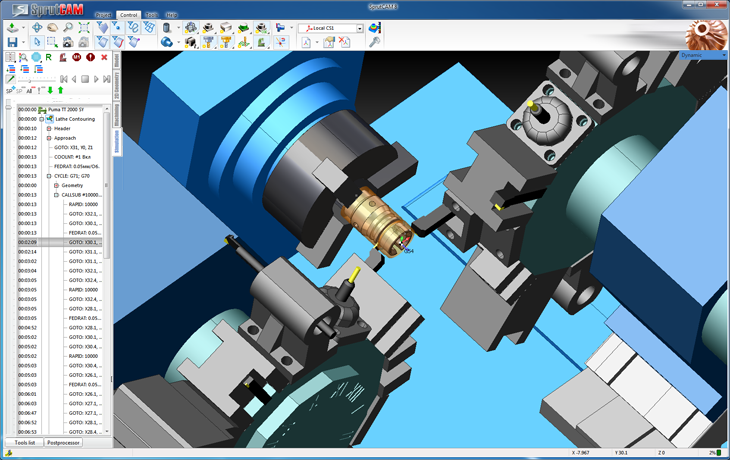

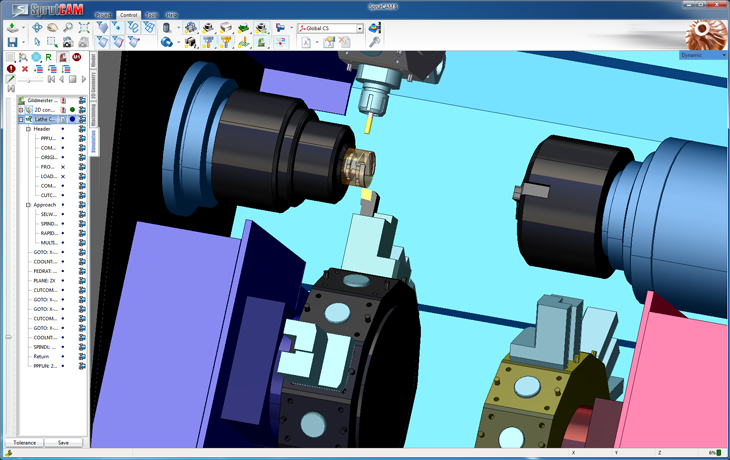

Contemporary CNC machines have a wide variety of machine mechanisms control procedures, such as part takeover from one spindle to another, boring of long parts held by two spindles, use of lunette, tailstock, stick feeder, catchers (pushers) of ready parts, loader of workpieces. Machines have their own rules and commands for the control of all of their mechanisms. SprutCAM enables the user to form set operations of control of any executive mechanisms of a machine, memorize them and include into a list for future use. Among such operations are for instance: the part take over from one to another spindle, the part taking by sub spindle and cut off, part clamping with lunette, part clamping by tailstock, automatic part outload to catcher, workpiece loader control. All the parameters, which have to be set in these operations are defined automatically when setting up the NC program in SprutCAM .

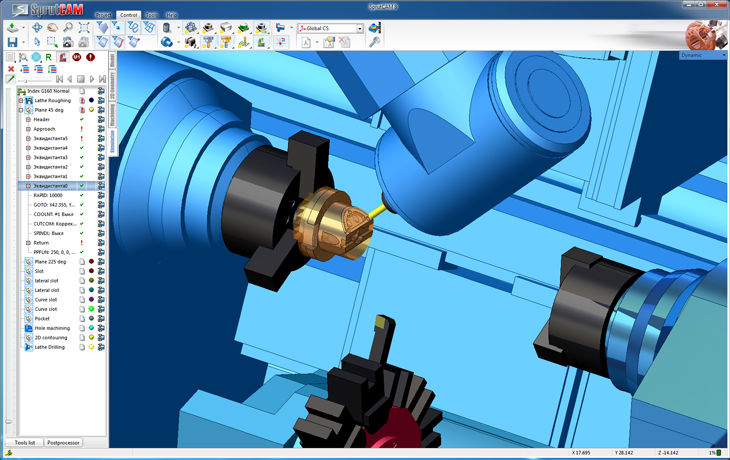

Machining simulation

Machining simulation at the stage of NC program creation permits to check exactly all the movements of the machine mechanisms taking into account the overhang of all the cutting tool installed in the turret heads of the machine in order to avoid collisions. Besides the visualization of the part machining the system enables to observe all the movements of the machine organs when carrying out auxiliary operations created by the system user, such as the part takeover from one to another spindle, the part taking by sub spindle and cut off, part clamping with lunette.

The machining simulation system carries out an automatic control of collisions of the cutting tool against all the machine’s elements, as well as a control of collisions between all the machine’s mechanisms.