VERTICAL

VERTICAL

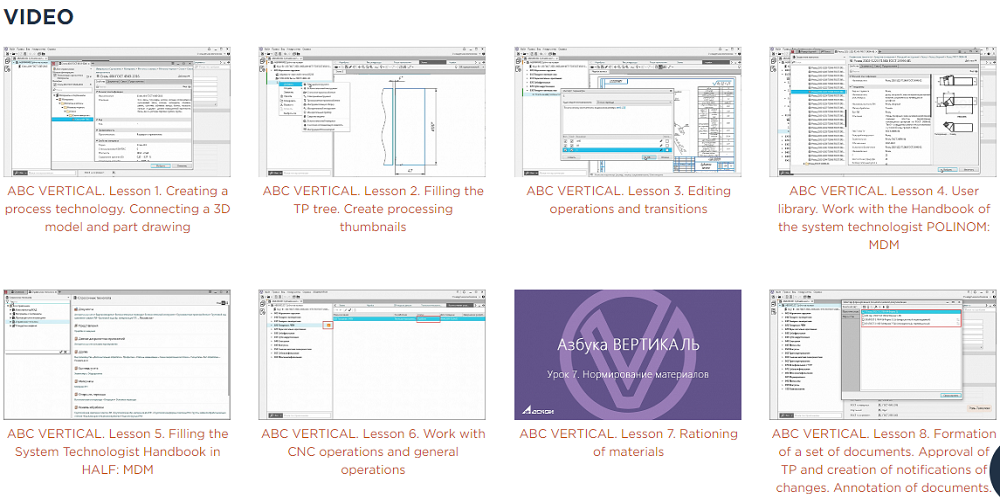

VERTICAL is a system of computer-aided design of technological processes that solves most of the problems within the framework of technological preparation of production and allows to simplify the formation and maintenance of technological processes, improve the quality of technological documentation and achieve optimal indicators of the use of available enterprise resources.

System features:

- Process Design

- Formation of orders for the design of service stations and the creation of control programs for CNC equipment

- Technological calculations

* Produced using settlement applications, which are delivered separately - Formation of technological documentation in accordance with the requirements of GOST RF and the standards used at the enterprise

- Support for a single information space for product lifecycle management

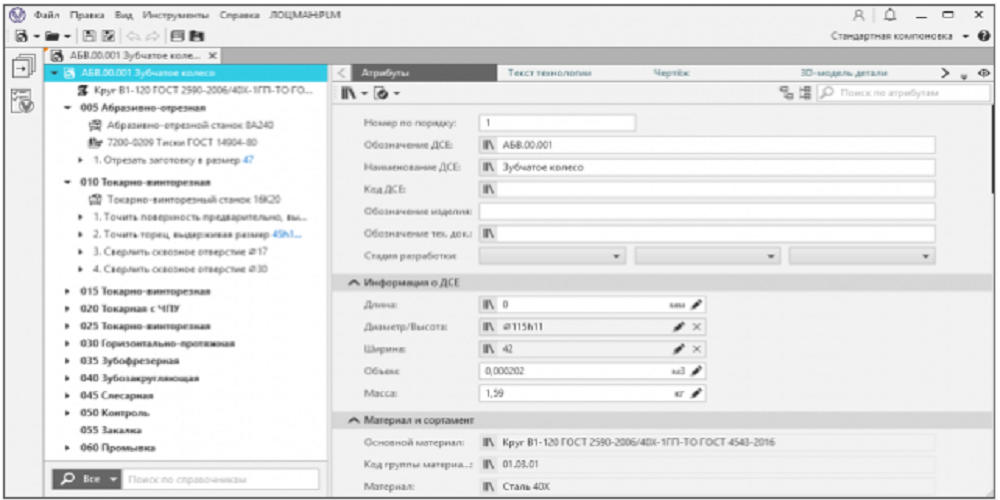

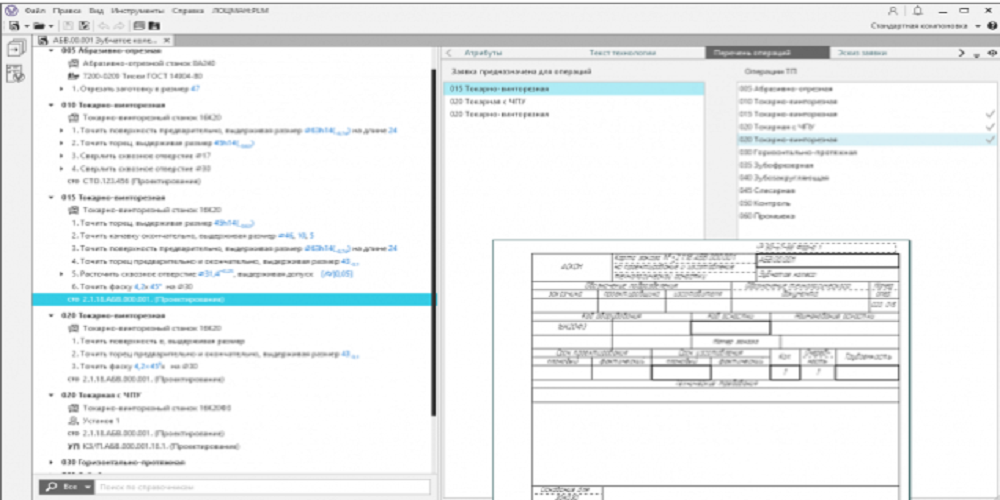

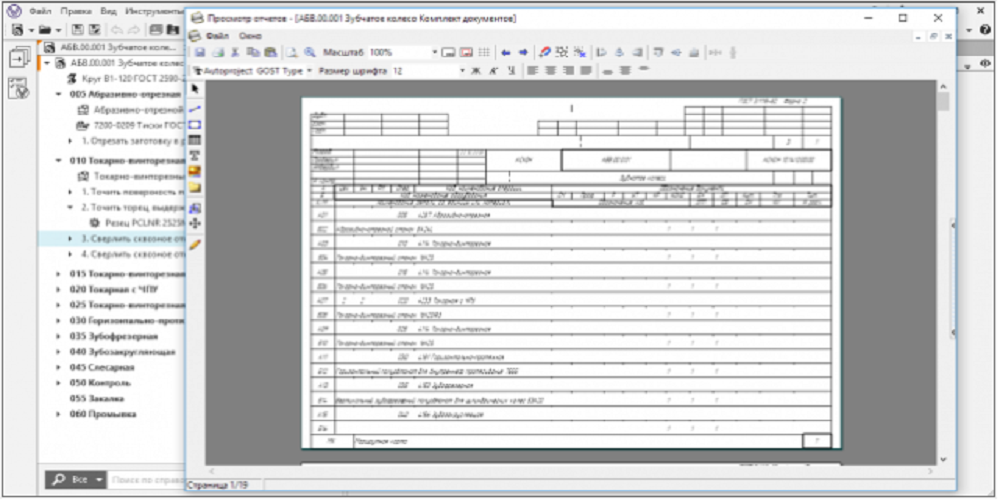

PROCESS DESIGN

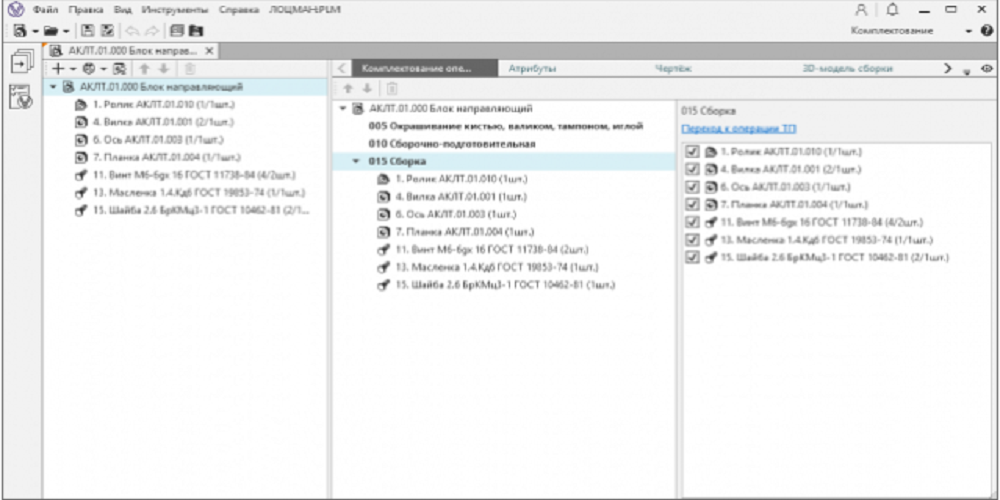

The VERTICAL system allows automated design of technological processes, which are based on a hierarchical structure of operations, transitions, equipment, professions, equipment and other technological objects, and also provides the possibility of parallel design of complex and end-to-end technological processes by a group of technologists in real time.

The development of standard and group technological processes is supported within the framework of which it is possible, once filling in the general data of TP, to use them subsequently for designing a multitude of individual technological processes.

As part of the work with the VERTICAL system, support is provided for the relevance of technological information through change management processes.

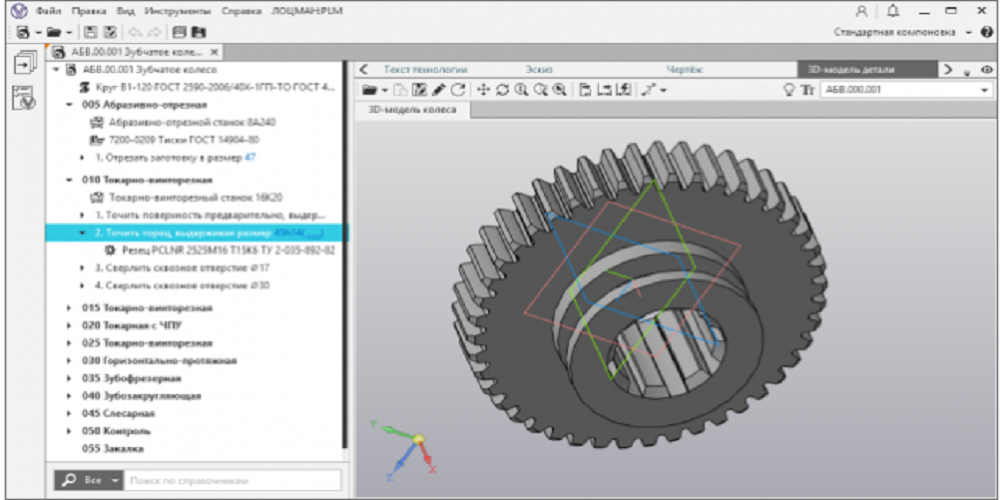

The system supports two-way communication of process parameters with parameters of KOMPAS-3D graphic documents: drawings, sketches, 3D models. When changing the parameter values in graphic documents, a corresponding change in the associated process parameters occurs (for example, resizing in the transition text when changing the corresponding dimension in the drawing). There is the possibility of a reverse action - updating the parameter value in a graphic document in response to changes in the TP.

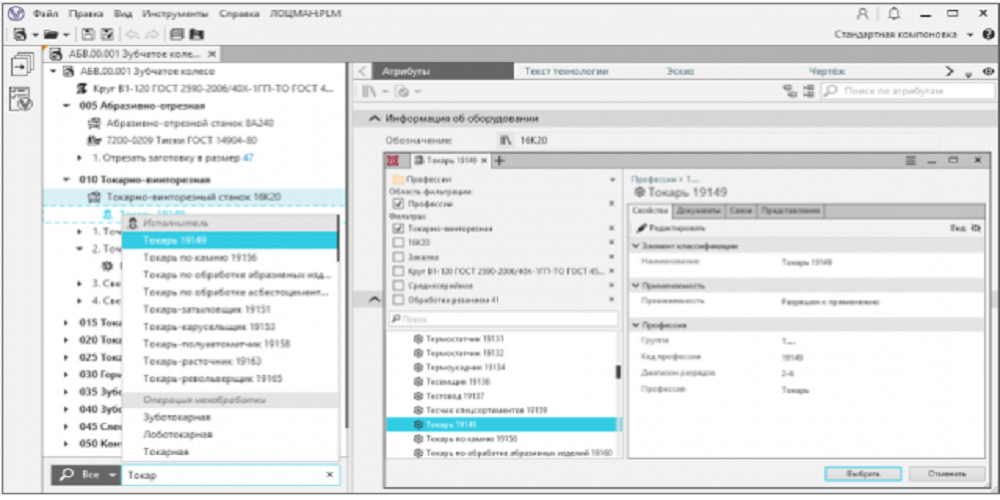

VERTICAL supports seamless integration with the reference management system POLIN: MDM. The search system implemented in VERTICAL allows you to find, add and replace process objects directly from the directories POLINOM: MDM without raising the system window. In this case, the search is carried out among those objects that can be applied taking into account the configured process model.

FORMATION OF ORDERS FOR THE DESIGN OF SERVICE STATIONS AND THE CREATION OF CONTROL PROGRAMS FOR CNC EQUIPMENT

The VERTICAL system implements the functions of generating applications for the design of technological equipment (STO) and control programs (UP) for CNC equipment. After the formation of the application, they are sent for approval to the appropriate services, while the approval of applications is possible when working with the LOTSMAN: PLM system

TECHNOLOGICAL CALCULATIONS

Specialized applications * allow you to carry out calculations in various areas of technological preparation of production:

* Delivered separately

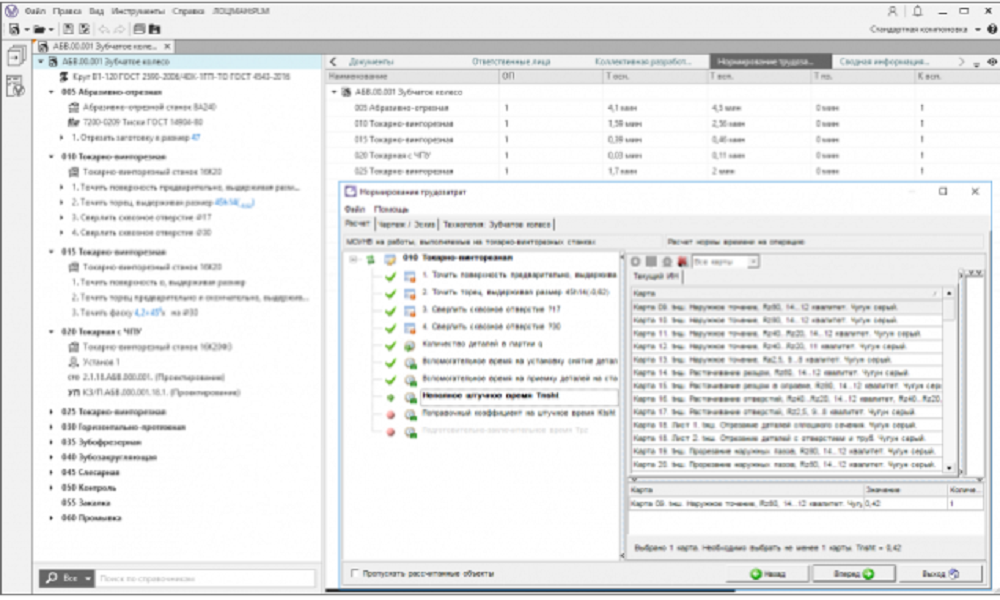

Labor rationing

The application Rationing of labor costs solves the problems of automated calculation of time spent on technological operations. The system implements various calculation methods depending on the degree of consolidation of labor costs (differentiated, enlarged, standard) from more than 50 collections of labor standards for various types of work (assembly, cutting, pressure, coating, welding, heat treatment, general operations destination, technical control, etc.)

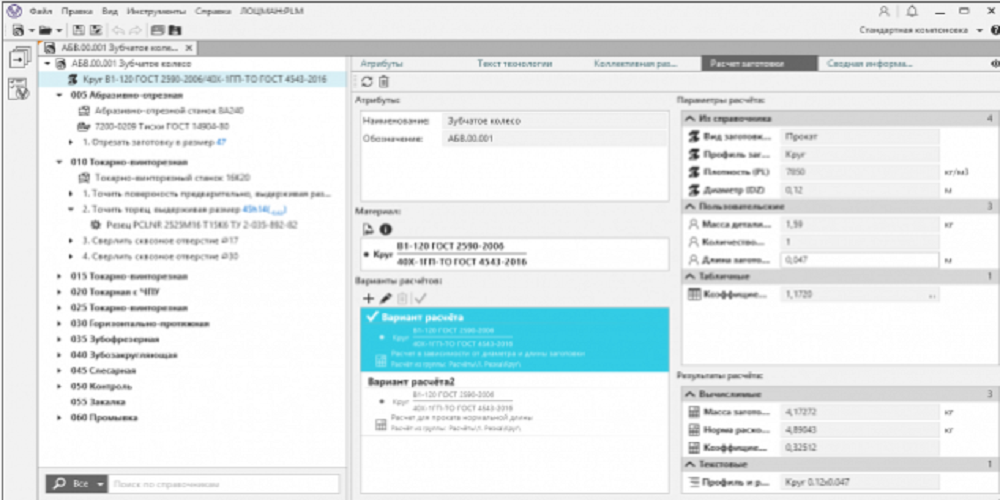

Rationing of materials

The application Rationing of materials allows solving the tasks of designing a workpiece for a part, calculating the mass of a workpiece, automating the calculation of the consumption rate of the main material and other standardization parameters in the technological departments of the enterprise.

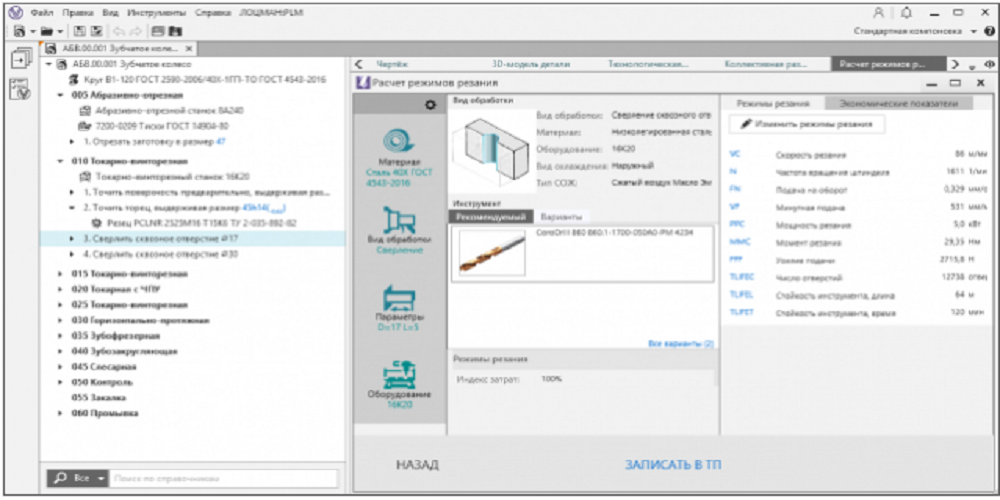

Calculation of cutting conditions

Calculation of cutting conditions - an application designed:

- for automated calculation of material processing parameters

- for selecting a tool depending on the characteristics of the material being processed, the geometrical parameters of the element being machined, the conditions of attachment, the type of cutting fluid, the calculation of the processing modes, and the calculation of the auxiliary time associated with the transition.

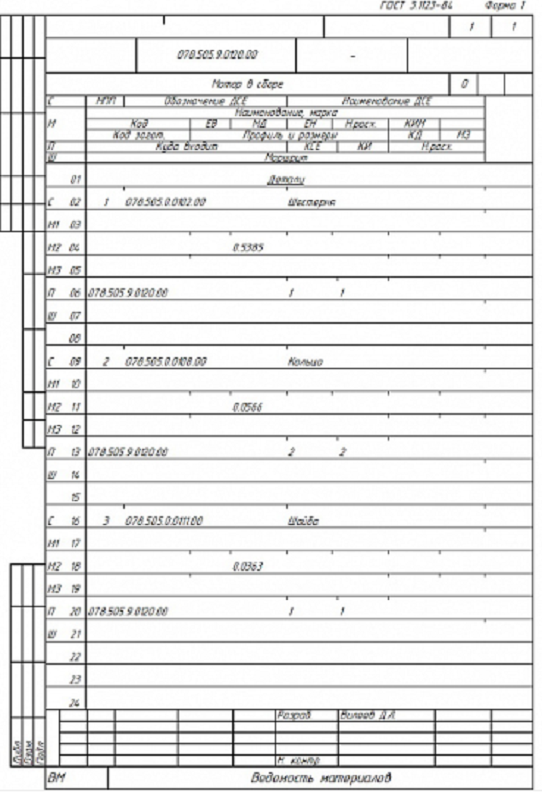

FORMATION OF TECHNOLOGICAL DOCUMENTATION IN ACCORDANCE WITH THE REQUIREMENTS OF GOST RF AND THE STANDARDS USED AT THE ENTERPRISE

After the development of the technological process, which contains all the necessary information for the manufacture of the product, is completed, the VERTICAL system allows the automatic generation of a set of technological documentation. In the basic delivery of the system there are most of the forms of documents provided for by GOST of the ESKD series (routing cards and statements).

The VERTICAL-Reports module allows you to create new reporting forms and data selection algorithms for placement on the form according to the requirements of the enterprise of almost any complexity.

A set of technological documents for a product may include documents containing information not only from a single technical process, but also a summary of technological information for all components of the product. As a rule, these are various statements, for example, a statement of specified consumption rates, a statement of materials, a statement of routes.

SUPPORT FOR A SINGLE INFORMATION SPACE FOR PRODUCT LIFECYCLE MANAGEMENT

The VERTICAL system can be used at the enterprise as an independent tool for solving problems of technological preparation of production, as well as integrate with other ASCON products, which allows you to include the system in a single CT3D solution for managing the product life cycle and creating a digital environment for joint product development and production preparation. As a result, the electronic description of the product contains the complete information necessary to support the stages of the product life cycle. At the stage of production preparation, the accumulation of data on the results of design and technological design and the exchange of information between engineering services is provided.

Edition: Professional and higher

Bit: x32 / x64

Trade In Substitution

DO YOU WANT TO AVOID THE RISK OF UNAUTHORIZED ACCESS TO DATA, BUT USE UNAPPROVED SOFTWARE? ARE YOU AFRAID OF DISCONNECTING FROM THE SUPPORT OF IMPORTED SOFTWARE AMID A WORSENING POLITICAL SITUATION? ARE YOU PLANNING TO FOLLOW THE COURSE OF IMPORT INDEPENDENCE, BUT HAVE NO IDEA WHAT TO DO WITH ALREADY ACQUIRED CAD AND PLM?

ASCON will help to take the first step towards import substitution using the Trade-in. Substitution ": we will take into account your investments and replace the licensed CAD or PDM / PLM of a foreign manufacturer with powerful and secure systems KOMPAS-3D / KOMPAS-Graph, LOTSMAN: PLM, CAD TP VERTICAL.

In 2014, KOMPAS-3D, CAD TP VERTICAL and LOTSMAN: PLM confirmed the status of protected software products by receiving certificates of the Federal Service for Technical and Export Control (FSTEC of Russia) for operation in the “For official use” circuit.

SPECIAL OFFER TO PROGRAM PARTICIPANTS

| Discount | |

| KOMPAS-3D | 65% of the standard price KOMPAS-3D |

| KOMPAS-Graph | 65% of the standard price KOMPAS-Graph |

| PILOT: PLM | 60% of the standard price PILOT: PLM |

| VERTICAL | 60% of the standard price VERTICAL |

| PILOT: KB | 60% of the standard price of the PILOT: KB |

Terms of participation in the Trade-in. Substitution ":

- The program applies to licensed users of any foreign computer-aided design (CAD) systems released earlier than 2017.

- All workplaces of the KOMPAS-3D, KOMPAS-Graph, LOTSMAN: PLM, VERTICAL systems purchased under the program are subject to the standard terms of technical support and updates. Applications for systems are purchased at a list price.

- Confirmation of the license cleanliness of the replaced software is a copy of the license agreement and software license numbers.

- Confirmation of the refusal to use the replaced software is an official letter of the organization.

Participate in the Trade-in. Substitution ":

be sure of safety - go to ours!

To participate in the KOMPAS program, fill out the application and send it to: tradein@ascon.ru or fax (812) 703-39-30 , 703-39-34 .

To participate in the Pilot Program: PLM and VERTICAL, fill out the application and send it to the address: complex@ascon.ru or by fax (812) 703-39-30 , 703-39-34 .